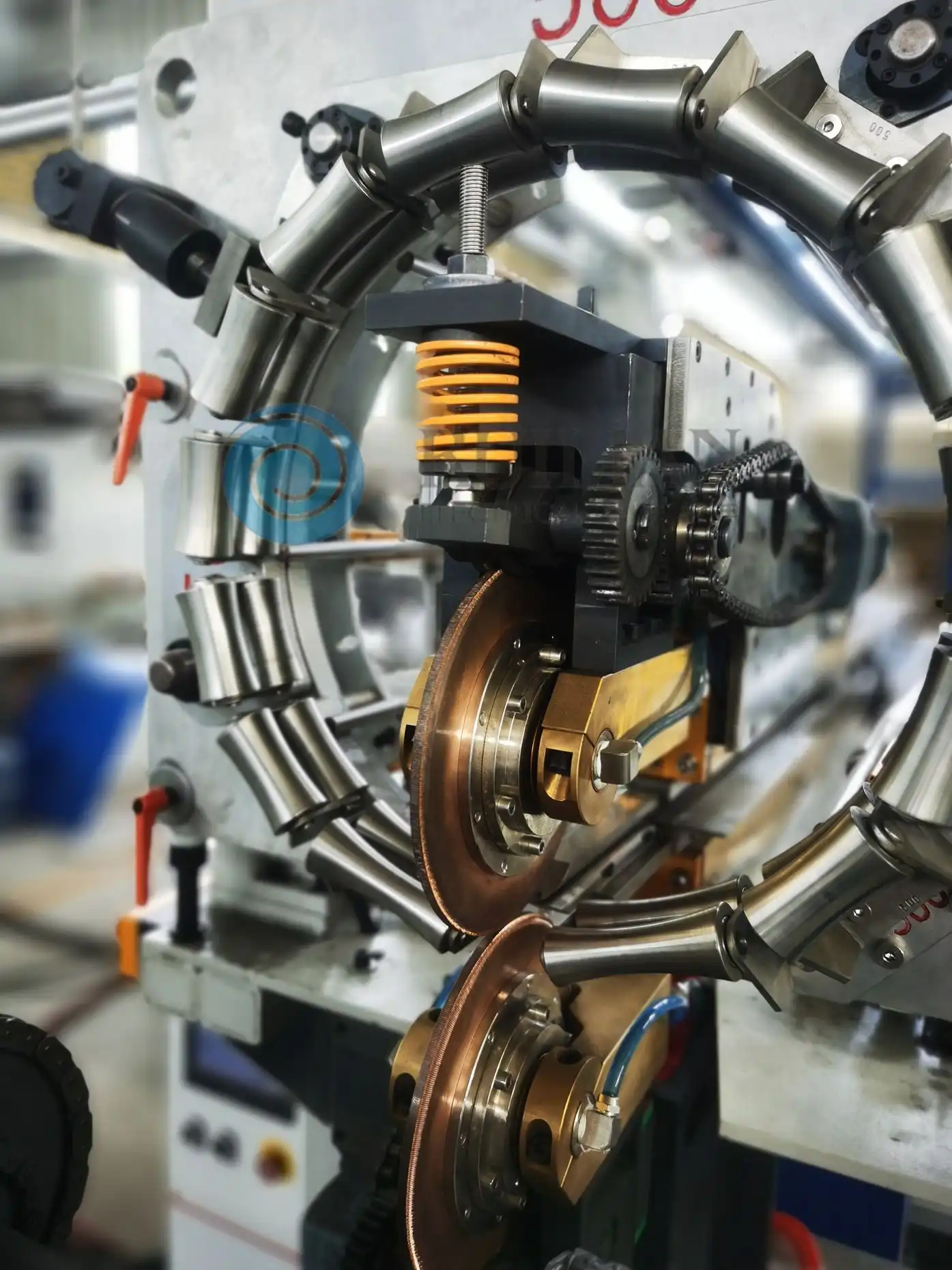

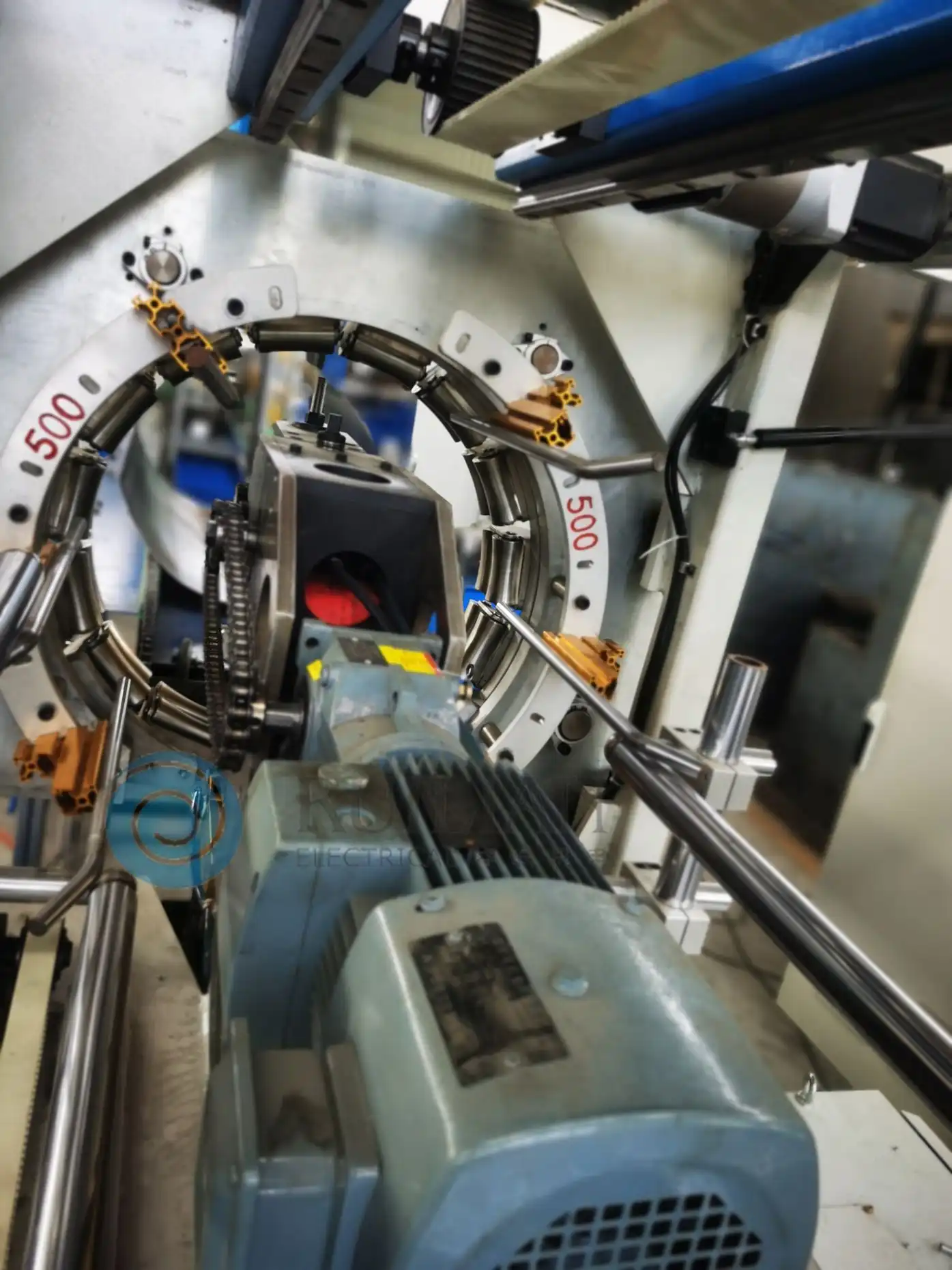

What is Steel Drum Automatic Welding Machine?

Are you looking for a reliable and efficient solution to enhance your drum manufacturing process? Our Steel Drum Automatic Welding Machine is designed specifically for manufacturers who demand precision, speed, and quality in their production lines.

Technical Parameters

| Parameter | Specification |

|---|---|

| Welding Diameter Range | 300mm - 600mm |

| Material Thickness | 0.4mm - 1.0mm |

| Welding Speed | Adjustable, up to 15m/min |

| Power Supply | 380V, 50Hz (Customizable) |

| Control System | PLC Control |

Product Features

| Feature | Description | Benefit |

|---|---|---|

| Welding Process | Multi-axis robotic arc welding (MIG/TIG customizable) | Precise control, deep penetration, reduced distortion |

| Vision System Integration | Real-time seam tracking and defect detection | Proactive quality control, minimized rework |

| Software Control | Intuitive HMI, PLC-based automation, data logging | Easy operation, process optimization, performance analysis |

| Power & Efficiency | High-frequency inverter technology, optimized energy usage | Lower operational costs, reduced environmental impact |

Application Fields

1. Drum Manufacturing: The machine is essential for the production of various types of drums, including oil drums, chemical drums, and industrial containers.

2. Packaging Industry: Drum bodies welded by this machine are widely used in the packaging industry for storage, transportation, and distribution of liquids and bulk materials.

3. Chemical Processing: Chemical drums produced by theAutomatic Drum Body Welding Machine are suitable for storing and transporting a wide range of chemicals, ensuring safety and compliance with industry regulations.

4. Logistics and Shipping: Welded drum bodies are integral to the logistics and shipping industry, providing durable and secure containment for goods during transportation.

Quality Control and Safety Standards

1. ISO Certification: The Automatic Drum Body Welding Machine meets international quality standards, guaranteeing superior performance and reliability.

2. Welding Standards: The machine adheres to strict welding standards and specifications, ensuring consistent weld quality and structural integrity.

3. Safety Compliance: Built-in safety features and adherence to industry safety standards prioritize operator safety and minimize workplace hazards.

4. Quality Assurance: Stringent quality control processes and inspections at every stage of production ensure that each automatic welding machine meets the highest standards of craftsmanship and performance.

Why Choose Us?

Expertise: With over 15 years in the industry, we understand the specific needs of drum manufacturers.

Quality Assurance: All machines undergo rigorous testing to ensure they meet the highest standards.

Global Reach: Our machines are used by manufacturers worldwide, reflecting our commitment to excellence.

FAQ:

| Question | Answer |

|---|---|

| What is the lead time for delivery? Do you provide training? What type of maintenance is required? |

Typically 6-8 weeks from order confirmation. |

| Yes, we offer comprehensive training for your team. | |

| Regular checks on welding parameters and machine parts are recommended. |

Contact Us

RUILIAN is your trusted partner in Steel Drum Automatic Welding Machine with years of experience. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.