What is Spot Welding Customization Machine?

The spot welding customization machine represents a cornerstone in modern manufacturing, offering unparalleled precision and efficiency in joining metal components. Engineered with advanced features and customizable options, it stands as a versatile solution for various industries, ensuring seamless welds and enhancing production processes. Whether used in automotive, electronics, or aerospace sectors, the machine delivers exceptional performance and reliability, meeting the most demanding production requirements.

Technical Parameters:

| Parameters | Specifications |

|---|---|

| Welding Current | 5-50 kA |

| Welding Method | AC/IF |

| Power Supply Voltage | 220V/380V 50/60 Hz |

| Rated Power | 25-200kW |

| Electrode Force | 100-20000 N |

| Cooling Method | Water Cooling |

| Control System | PLC Control |

| Machine Weight | 1500-3000 kg |

| Dimensions (LWH) | Customizable |

Product Features:

✅ Increase production efficiency by up to 40%

✅ Reduce labor costs by 30-50%

✅ Achieve consistent, high-quality welds

✅ Customize for various product designs

✅ Seamless integration with existing production lines

Application Fields:

- Automotive Industry:Used for medium frequency welding body panels, chassis components, and structural assemblies, ensuring structural integrity and durability.

- Electronics Manufacturing:Applied in the production of circuit boards, electrical connectors, and battery packs, ensuring reliable electrical connections.

- Aerospace Sector: Critical for manufacturing aircraft components, including fuselage panels, engine mounts, and structural reinforcements, where precision and reliability are paramount.

Quality Control and Safety Standards:

- ISO Certification: produced in accordance with ISO quality management standards, guaranteeing consistent performance and quality.

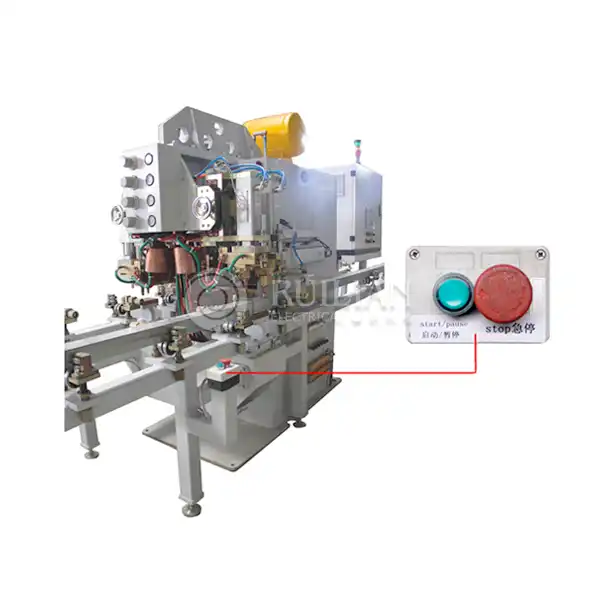

- Safety Features: Equipped with safety features such as emergency stop buttons and safety interlocks to protect operators from hazards.

- Quality Assurance: At each phase of creation, tough quality control measures guarantee prevalent weld quality and constancy.

Why Choose Us?

- Industry Experience: Since we have been producing welding equipment for a lot of time, we have the skill important to give inventive and reliable arrangements.

- Customization: Our machines are fully customizable to meet the unique requirements of each customer, ensuring optimal performance and efficiency.

- Quality Assurance: We stick to quality control norms to guarantee that our items are of the greatest conceivable quality and trustworthiness.

- Technical Support: Our dedicated technical support team provides prompt assistance and ensures smooth operation throughout the product lifecycle.

Contact Us

spot welding customization machine from RUILIAN exemplifies precision, reliability, and versatility, making it the preferred choice for industries worldwide. Contact us atry@china-ruilian.cn and hm@china-ruilian.cn.