What is Resistance Straight Seam Welding Machine?

The Resistance Straight Seam Welding Machine is a top tier current welding gadget expected to convey prevalent execution in welding applications. This machine ensures a strong and durable bond by joining materials along a straight crease in accordance with opposition welding standards. It is involved a great deal in assembling, aviation, development, auto, and different fields where strength and accuracy are significant.

Technical Parameter Table

| Parameter | Specification |

|---|---|

| Welding Type | Resistance Straight Seam Welding |

| Welding materials | Mild steel plate/galvanized steel plate/stainless steel plate |

| Welding Current | 1000A - 20000A |

| Welding Speed | 0.5 - 9 meters per minute |

| Electrode Force | 500N - 10000N |

| Max Welding Thickness | Up to 1.2mm (depending on material) |

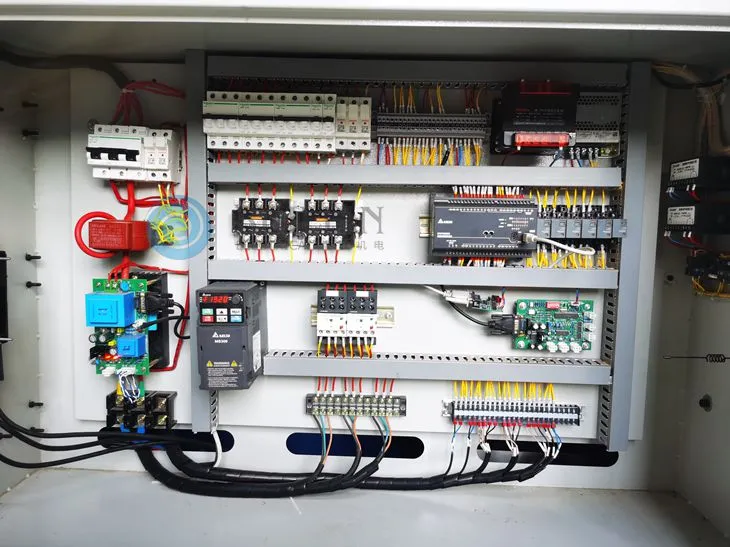

| Control System | PLC with HMI Interface |

| Cooling System | Water-cooled |

| Electrode Material | Copper Alloy |

| Machine Dimensions (LxWxH) | Customizable |

| Weight | Varies by model |

| Certification | CE, ISO 9001:2015 |

Product Features

The Resistance Straight Seam Welding Machine is designed with numerous features to ensure optimal performance, ease of use, and durability. Here are some key features:

1.High Welding Speed: Capable of welding at speeds up to 15 meters per minute, enhancing productivity and efficiency in industrial applications.

2.Adjustable Welding Parameters: Operators can adjust welding current, pressure, and speed to suit different materials and thicknesses, ensuring versatility.

3.PLC Control System: The machine is equipped with a PLC control system with an HMI interface, allowing for precise control and easy monitoring of the welding process.

4.Durable Construction: Built with high-quality materials to withstand rigorous industrial use and ensure long-term reliability.

5.Water-Cooled Electrodes: The water-cooling system prevents overheating, maintaining electrode integrity and extending their lifespan.

6.User-Friendly Interface: The HMI interface provides a user-friendly platform for setting and adjusting welding parameters, making the machine easy to operate.

7.Safety Features: Includes emergency stop buttons, overload protection, and safety interlocks to ensure the safety of operators and equipment.

8.Consistent Weld Quality: Ensures uniform heating and pressure application, resulting in consistent and high-quality weld seams.

9.Versatile Applications: Suitable for welding a variety of metals, including steel, stainless steel, and aluminum, making it versatile for different industrial needs.

10.Low Maintenance: Designed for easy maintenance, with accessible components and a robust build that reduces the need for frequent repairs.

Application Fields

The versatility and efficiency of the resistance straight seam welding machine suitable for a wide range of applications:

Automotive Industry: Ideal for body, chassis, and fuel tank welding.

Appliance Manufacturing: Perfect for welding refrigerator, washing machine, and water heater casings.

Metal Products: Suitable for pipes, tanks, and pressure vessels.

Construction: Efficient for steel structures, doors, and windows.

Other Sectors: Applicable in packaging, furniture, and any industry requiring metal sheet welding.

Certifications:

• CE Certified

• ISO 9001:2015 Quality Management System

• ISO 14001:2015 Environmental Management System

Why Choose Us?

Choosing our product means partnering with a company that prioritizes quality, innovation, and customer satisfaction. Here are some reasons why you should choose us:

1.Experienc: With years of experience in the industry, we have the expertise to deliver high-quality welding machines that meet your needs.

2.Innovation: We continuously invest in research and development to bring you the latest advancements in welding technology.

3.Quality: Our machines are built to the highest standards of quality and reliability, ensuring long-term performance and durability.

4.Customization: We offer customizable solutions to meet your specific requirements, ensuring you get the machine that best fits your needs.

FAQ:

Q1: What maintenance does the machine require?

A1: Regular checks on the electrical components and mechanical parts, with annual servicing recommended.

Q2: Can the machine handle different materials?

A2: Yes, it's designed for various metals including steel, stainless steel, and aluminum.

Q3: How long is the warranty period?

A3: We offer a 2-year warranty on parts and labor, extendable with maintenance contracts.

Q4: Is training provided for operators?

A4: Yes, we offer comprehensive training sessions for your team at our facility or yours.

Q5: What are the payment terms?

A5: We offer flexible payment options including L/C, T/T, and installment plans for large orders.

Contact Us

RUILIAN, a professional manufacturer and supplier with many years of experience in producing Resistance Straight Seam Welding Machine, offers independent research and development, self-production and sales, batch orders, and customized services. If you are interested, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.