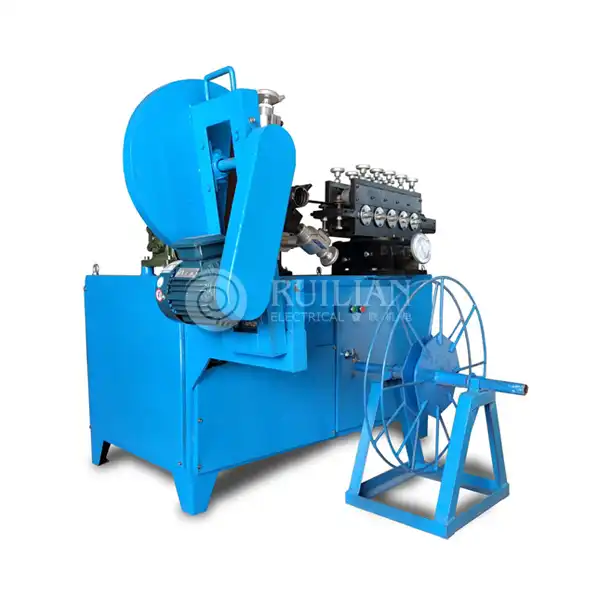

What is Kitchen Appliance Basin Seam Welding Machine?

Our Kitchen Appliance Basin Seam Welding Machine is designed for high-quality and efficient welding of kitchen appliance basins. This machine ensures durable and reliable seams, meeting the stringent standards of the kitchen appliance industry.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Welding Method | Resistance Seam Welding |

| Welding Speed | 2 - 6m/min |

| Welding Thickness | 0.3 - 1.5 mm |

| Power Supply | 220V/380V, 50/60Hz |

| Basin Diameter | 200 - 800 mm |

| Motor Power | 100kW |

| Control System | PLC Control |

| Dimensions (L×W×H) | 3000×1500×1800 mm |

| Weight | 1500 kg |

Product Features:

Precise Seam Welding: Achieve consistent, high-quality welds with our advanced welding technology.

Increased Production Capacity: Boost your output with a machine designed for high-volume production.

Reduced Labor Costs: Automate the welding process, freeing up your workforce for other tasks.

Durable and Reliable: Built with high-quality materials and components for long-lasting performance.

User-Friendly Interface: Easy-to-use controls and intuitive programming for seamless operation.

Application Fields:

- Kitchen Appliance Manufacturing: The Kitchen Appliance Basin Seam Welding Machine is essential for producing various kitchen equipment, including sinks, basins, and countertops.

- Commercial Kitchens: Used in restaurants, hotels, and catering facilities for the fabrication of stainless steel sinks and basins.

- Residential Applications: Ideal for manufacturing kitchen sinks and basins for residential homes and apartments.

- Industrial Kitchens: Employed in industrial settings for the production of stainless steel basins for food processing and manufacturing facilities.

Equipment Composition:

- Welding Head: Houses the electrodes and controls the welding process.

- Clamping System: Secures the basin components in place during welding.

- Power Supply Unit: Provides the necessary electrical power for welding operations.

- Control Panel: Interface for setting and monitoring welding parameters.

- Cooling System: Ensures optimal operating temperature for the machine components.

Quality Control and Safety Standards:

- ISO Certification: Compliance with international quality management standards ensures consistent quality and customer satisfaction.

- Safety Features: Incorporation of safety interlocks, emergency stop buttons, and protective enclosures to prevent accidents and ensure operator safety.

- Quality Assurance: Rigorous testing and inspection procedures throughout the manufacturing process to maintain high product quality and reliability.

- Documentation: Maintain detailed records of production processes and quality control measures for traceability and accountability.

- Continuous Improvement: Commitment to continuous improvement initiatives to enhance product quality, efficiency, and safety standards.

Why Choose RUILIAN?

- Industry Leadership: RUILIAN is a trusted leader in the welding equipment industry, with decades of experience and expertise.

- Innovation and Research: RUILIAN invests in research and development to continuously improve its products and introduce innovative solutions.

- Quality Assurance: With stringent quality control measures, RUILIAN ensures that its products meet the highest standards of performance and reliability.

- Customer-Centric Approach: RUILIAN prioritizes customer satisfaction, offering personalized service and support to meet individual needs.

- Global Reach: With a global network of partners and distributors, RUILIAN serves customers worldwide, providing timely and efficient solutions to their welding needs.

Contact Us

As a leading Kitchen Appliance Basin Seam Welding Machine manufacturer and supplier, RUILIAN is committed to delivering superior products, technical expertise, and exceptional customer service. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.