What is Steel Drum Lifting Beam Automatic Spot Welding Machine?

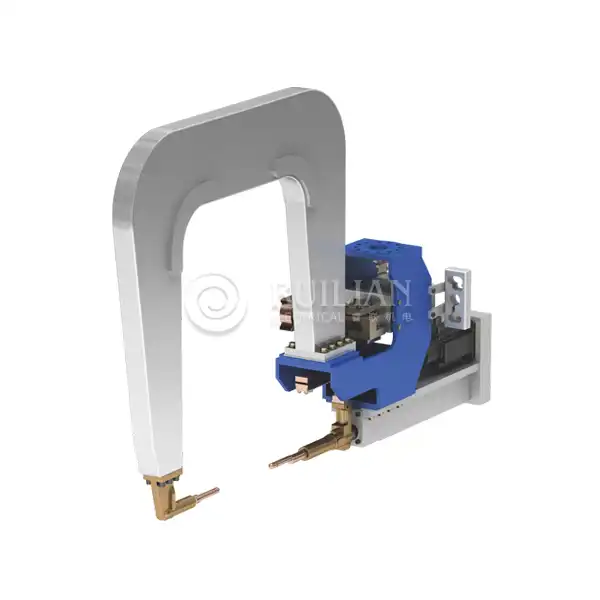

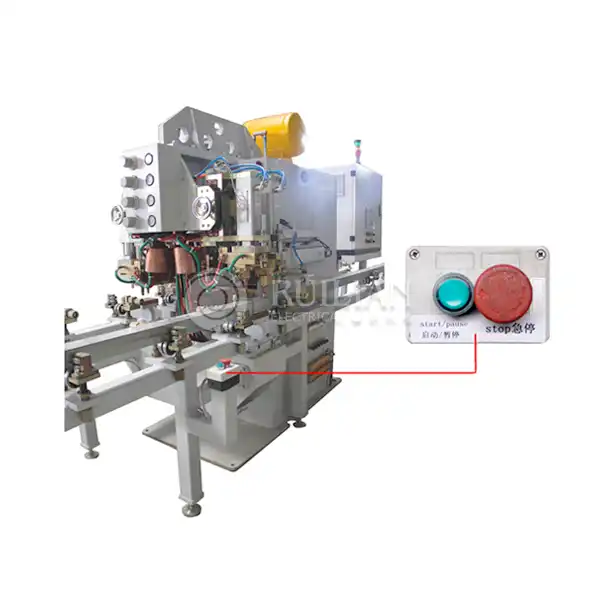

The Steel Drum Lifting Beam Automatic Spot Welding Machine is a state-of-the-art industrial device designed to streamline the welding process for lifting beams on steel drums. Lifting beams are critical components that allow steel drums to be safely handled, transported, and stored. This machine automates the spot welding process, ensuring that lifting beams are securely and accurately attached to the drums, which enhances the overall strength and safety of the finished product.

Technical Parameter

| Parameter | Specification |

|---|---|

| Input Voltage | 220V/380V , 50/60Hz |

| Power Consumption | 35kW |

| Welding Current Range | 1500A - 10000A |

| Welding Pressure Range | 0.5-1.0 MPa |

| Electrode Stroke | 15mm - 50mm |

| Cooling System | Water Cooling |

| Control System | PLC with Touchscreen Interface |

| Welding Speed | Up to 15 cycles/min |

| Dimensions (L x W x H) | 2000mm x 1200mm x 1800mm |

| Weight | 1000 kg |

Product Features

| Feature | Benefit |

|---|---|

| Advanced PLC Control | Ensures precise welding parameters and consistent quality |

| Multi-point Welding | Strengthens drum structure for enhanced durability |

| Quick-change Tooling | Minimizes downtime during product changeovers |

| Energy-efficient Design | Reduces operational costs and environmental impact |

| Compact Footprint | Saves valuable floor space in your facility |

Application Fields

1. Steel Drum Manufacturing: Essential for the production of steel drums, ensuring that lifting beams are securely attached for safe handling and transportation.

2. Chemical Industry: Used in the production of steel drums for storing and transporting hazardous materials, ensuring the structural integrity and safety of the containers.

3. Petroleum Industry: Vital for manufacturing steel drums used to transport oil and other petroleum products, ensuring the reliability and safety of these critical containers.

4. Food and Beverage Industry: Suitable for producing steel drums that store and transport bulk liquids and solids, ensuring that the drums meet food-grade standards.

5. Pharmaceutical Industry: Ensures the production of steel drums used for storing and transporting sensitive materials, meeting the stringent quality standards required in this field.

Quality Control and Safety Standards

1. ISO Certification: Built to comply with ISO standards, ensuring reliability and performance.

2. Regular Inspections: Frequent quality checks verify that each machine meets required specifications, ensuring consistent performance.

3. Safety Protocols: Designed with numerous safety protocols, including automated shutdowns in case of faults and protective guards around critical components.

4. Training Programs: Comprehensive training ensures operators are well-versed in the machine’s operation and safety procedures.

5. Compliance with Industry Standards: Meets various industry standards, including CE marking for European markets and other relevant certifications.

Why Choose Us?

1. Expertise and Experience: Years of experience in manufacturing and supplying Steel Drum Lifting Beam Automatic Spot Welding Machines.

2. Innovative Technology: Machines incorporate the latest technological advancements for superior performance and efficiency.

3. Comprehensive Support: Extensive after-sales support, including technical assistance, training, and spare parts supply.

4. Customization: Machines can be customized to meet specific requirements, ensuring they perfectly fit your production processes.

5. Global Reach: Strong global presence to serve customers worldwide, providing timely and effective support.

Contact Us

RUILIAN, a professional manufacturer and supplier with many years of experience in producing Steel Drum Lifting Beam Automatic Spot Welding Machines, If you are interested in our products, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.