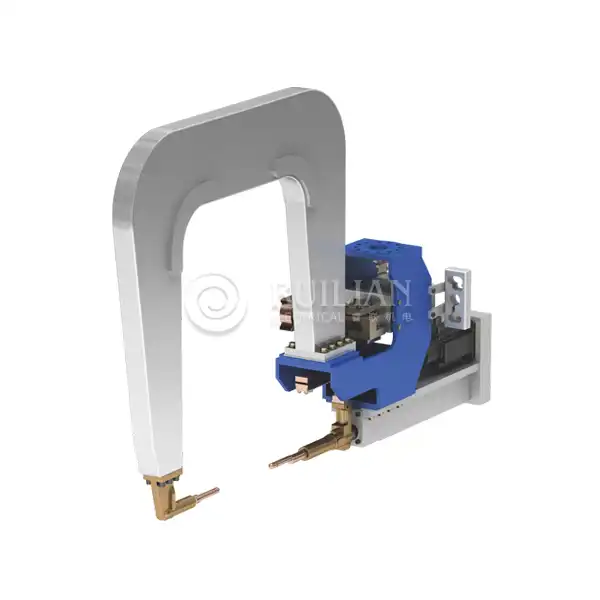

What is Simple Seam Welding Machine?

The Simple Seam Welding Machine represents the epitome of efficiency and precision in the manufacturing process of kitchen appliance basins. This advanced machine is meticulously engineered to seamlessly weld basin components, ensuring impeccable quality and durability.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Welding Method | Resistance Seam Welding |

| Welding Speed | 2 - 6m/min |

| Welding Thickness | 0.3 - 1.5 mm |

| Power Supply | 220V/380V , 50/60Hz |

| Welding Length | 100 - 1500mm |

| Motor Power | 100kW |

| Control System | PLC Control |

| Dimensions (L×W×H) | 3000×1500×1800 mm |

| Weight | 1500 kg |

Product Features:

| Feature | Description |

|---|---|

| Ease of Use | User-friendly interface, suitable for operators of all skill levels. |

| Durability | Robust construction for long-term industrial use. |

| Precision Welding | Consistent seam quality with adjustable settings for various materials. |

| Safety Features | Emergency stop, thermal overload protection. |

| Energy Efficiency | Optimized power usage to reduce operational costs. |

| Maintenance | Low maintenance requirements with easy access for repairs. |

| Footprint | Compact design to fit in limited workspace. |

Simple Seam Welding Machine Application Fields:

Automotive Manufacturing: Precision welding for vehicle components.

Aerospace: High-strength welds for critical aerospace parts.

Metal Fabrication: Versatile welding for various metal products.

Appliance Manufacturing: Seam welding for durable home appliances.

Heavy Machinery: Reliable welds for industrial machinery components.

Quality Control and Safety Standards:

- ISO Certification: Compliance with international quality management standards ensures consistent quality and customer satisfaction.

- Safety Features: Incorporation of safety interlocks, emergency stop buttons, and protective enclosures to prevent accidents and ensure operator safety.

- Quality Assurance: Rigorous testing and inspection procedures throughout the manufacturing process to maintain high product quality and reliability.

- Documentation: Maintain detailed records of production processes and quality control measures for traceability and accountability.

- Continuous Improvement: Commitment to continuous improvement initiatives to enhance product quality, efficiency, and safety standards.

Why Choose RUILIAN?

- Industry Leadership: RUILIAN is a trusted leader in the welding equipment industry, with decades of experience and expertise.

- Innovation and Research: RUILIAN invests in research and development to continuously improve its products and introduce innovative solutions.

- Quality Assurance: With stringent quality control measures, RUILIAN ensures that its products meet the highest standards of performance and reliability.

- Customer-Centric Approach: RUILIAN prioritizes customer satisfaction, offering personalized service and support to meet individual needs.

- Global Reach: With a global network of partners and distributors, RUILIAN serves customers worldwide, providing timely and efficient solutions to their welding needs.

Contact Us

As a leading manufacturer and supplier, RUILIAN is committed to delivering superior Simple Seam Welding Machine. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.