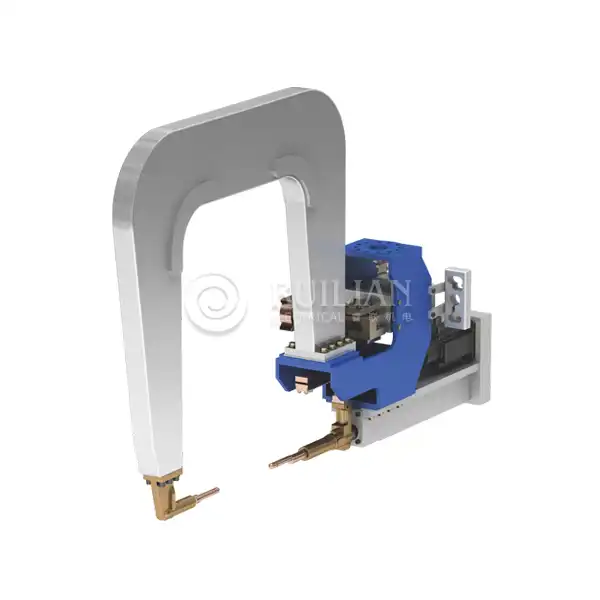

What is Circumferential Resistance Welding Machine?

Welcome to RUILIAN, the place where innovation and precision meet. For the most demanding applications, our circumferential resistance welding machine is designed to produce high-quality welds. In accordance with international standards, our machine produces precise welds for industries like aerospace, automotive, oil and gas, machinery, and electrical equipment.

Technical Parameter

| Parameter | Specification |

|---|---|

| Welding Type | Circumferential Resistance Welding |

| Welding diameter | 30 - 300mm (Customizable) |

| Welding Current | 500A - 10000A |

| Welding Speed | 0.5 - 3 meters per minute |

| Electrode Force | 300N - 10000N |

| Max Welding Thickness | Up to 1.0mm (depending on material) |

| Control System | PLC with HMI Interface |

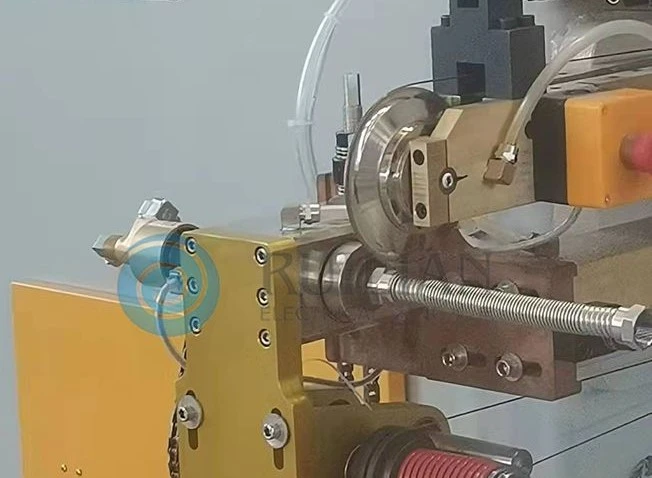

| Cooling System | Water-cooled |

| Electrode Material | Copper Alloy |

| Machine Dimensions (LxWxH) | Customizable |

| Weight | Varies by model |

| Certification | CE, ISO 9001:2015 |

Product Features

The Circumferential Resistance Welding Machine boasts a range of features designed to ensure optimal performance, ease of use, and durability:

High Precision: Ensures consistent weld quality even during long production runs.

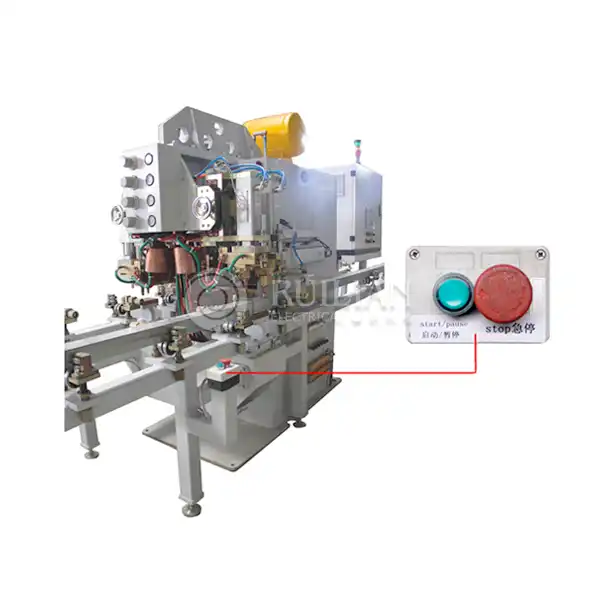

Automation: Reduces manual labor and increases production efficiency.

Versatility: Capable of handling multiple materials and varying specifications.

Safety and Stability: Complies with industry standards (ISO, ASME) with high safety features.

Advanced Control Systems: CNC/PLC control for precise and repeatable operations.

Robust Construction: Durable build quality ensures long-term reliability.

Application Fields

Our Circumferential Resistance Welding Machine is widely used in the following industries:

Aerospace: Production of fuel tanks, pressure vessels, and other critical components.

Automotive: Manufacturing of exhaust systems, fuel tanks, and drive shafts.

Oil and Gas: Fabrication of storage tanks and pipelines.

Heavy Machinery: Creation of large hydraulic cylinders and boilers.

Electrical Equipment: Welding of motor housings, transformers, and similar

Quality Control and Safety Standards

Quality control and wellbeing are basic parts of the product's activity. Here are the actions and principles we stick to:

1.Certification under ISO 9001:2015: Our machines are produced in consistence with ISO 9001:2015 quality administration norms, guaranteeing consistency and dependability.

2.CE Certification: The machine meets European wellbeing and execution principles, giving confirmation of its quality and security.

Why Choose Us?

Industry Leadership: Renowned for our expertise and innovation in welding technology.

Customer-Centric Approach: Tailored solutions to meet specific client needs.

Comprehensive Support: From consultation to after-sales service, we ensure seamless integration and operation.

Proven Track Record: Extensive portfolio of successful projects and satisfied clients globally.

Technological Superiority: Continuous investment in R&D to provide cutting-edge solutions.

FAQ:

Can this machine be customized to suit specific needs?

Yes, we offer customization options such as automated loading/unloading systems, remote monitoring, and more.

What materials can the machine weld?

The machine is compatible with materials like stainless steel, aluminum, titanium, and Inconel.

What kind of maintenance does the machine require?

Routine maintenance includes checking the cooling system, inspecting electrodes, and ensuring the control system is functioning properly. We provide a detailed maintenance manual and training.

How long does it take to deliver the machine?

Standard delivery time is 10-12 weeks, depending on customization requirements.

What kind of support do you offer after purchase?

We offer comprehensive support, including installation, operator training, and 24/7 technical assistance.

Contact Us

RUILIAN, a professional manufacturer and supplier with many years of experience in producing Circumferential Resistance Welding Machine, offers independent research and development, self-production and sales, batch orders, and customized services. If you are interested, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.