What is Fuel Tank Seam Welding Customization Machine?

Fuel tank manufacturing demands precision and durability. The fuel tank seam welding customization machine stands as the epitome of innovation in this niche. At the forefront of advanced manufacturing, this machine streamlines the welding process with customizable features tailored to meet the unique demands of fuel tank fabrication. Engineered for efficiency and reliability, it embodies cutting-edge technology to ensure seamless welds and exceptional quality.

Technical Parameters:

| Parameters | Specifications |

|---|---|

| Welding Speed | 0.5-2.5 m/min |

| Welding Thickness | 0.5-3 mm |

| Power Supply Voltage | 220V/380V 50/60 Hz |

| Welding Throat Depth | 1000mm |

| Rated Power | 100kW |

| Cooling Method | Water Cooling |

| Control System | PLC Control |

| Welding Seam Tracking System | Laser or Vision System |

| Machine Weight | 1500-3000 kg |

| Dimensions (LWH) | Customizable |

Product Features:

- Customization: Tailored to meet the precise requirements of fuel tank fabrication, with adjustable parameters for weld speed, thickness, and seam tracking.

- High Precision: Utilizes advanced technology to achieve precise welds, ensuring leak-proof and durable fuel tanks.

- Efficiency: Rapid welding speeds and automated processes streamline production, reducing cycle times and increasing productivity.

- User-Friendly Interface: Intuitive controls and a user-friendly interface make operation straightforward, minimizing training requirements.

- Reliability: Robust construction and quality components ensure long-term reliability and minimal downtime.

Application Fields:

- Automotive Industry: Used in the production of fuel tanks for automobiles, ensuring reliable and leak-proof welds.

- Aerospace Sector: Critical for manufacturing fuel tanks for aircraft, where safety and durability are paramount.

- Energy Sector:Applied in the fabrication of fuel storage tanks for generators and power plants, ensuring optimal performance and reliability.

Equipment Composition:

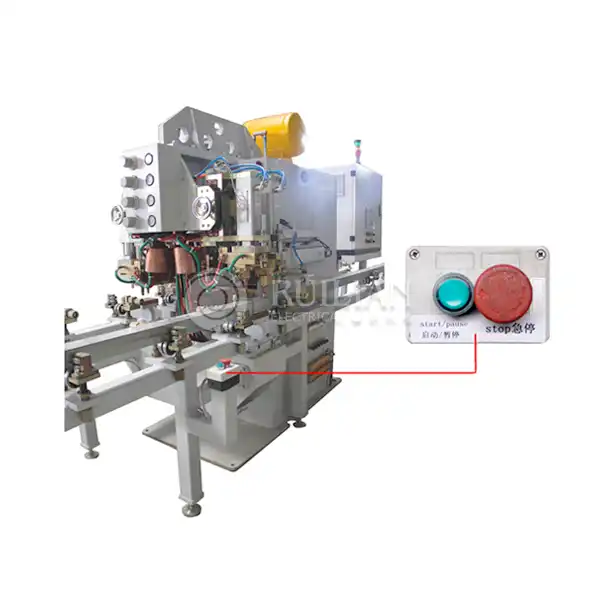

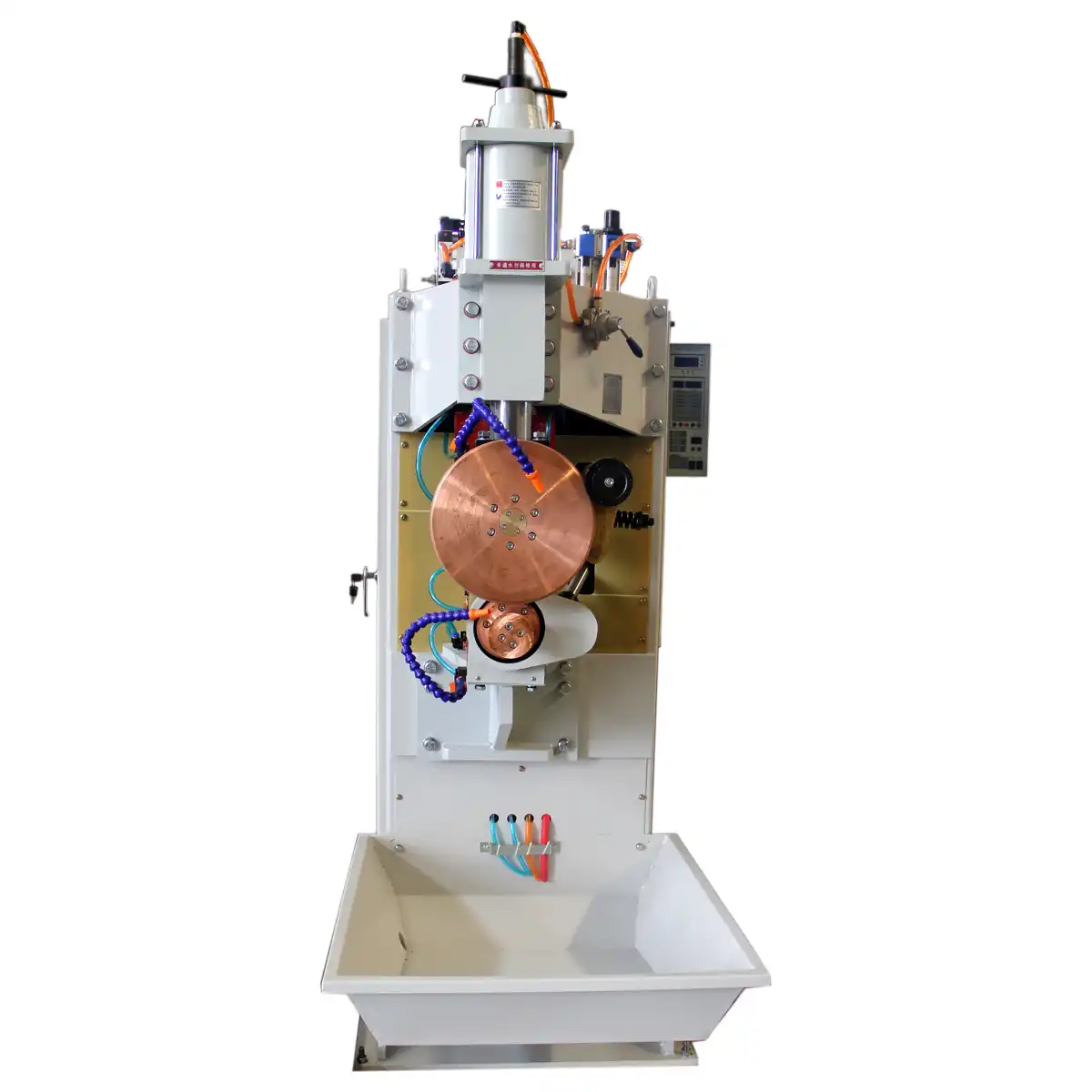

- Welding Head: Houses the welding electrode and controls the welding process.

- Clamping System:Secures the workpieces in position during welding.

- Control Panel: Interface for setting welding parameters and monitoring the process.

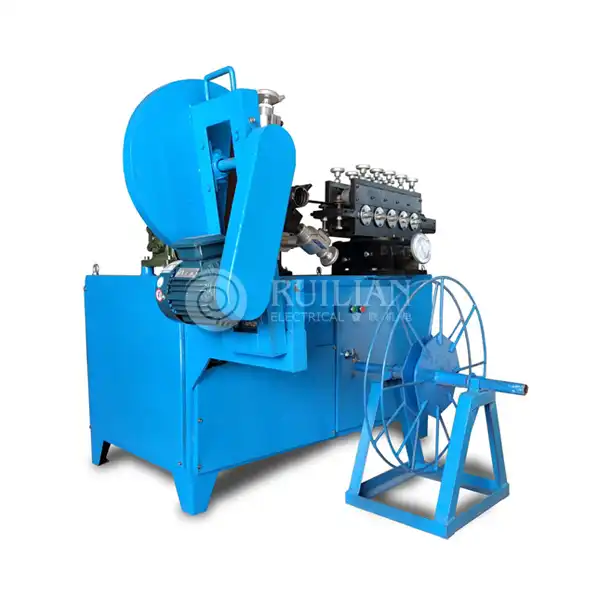

- Cooling System: Maintains optimal temperature control during welding operations.

- Seam Tracking System:Laser or vision systems track the welding seam, ensuring accuracy and consistency.

Quality Control and Safety Standards:

- ISO Certification: Manufactured in compliance with ISO quality management standards, ensuring consistent quality and performance.

- Safety Features:Equipped with safety features such as emergency stop buttons and safety guards to protect operators from hazards.

- Quality Assurance:Rigorous quality control measures at every stage of production guarantee superior weld quality and reliability.

Why Choose Us?

- Industry Experience:We have the expertise to provide innovative and dependable solutions thanks to our years of welding equipment manufacturing experience.

- Customization:Our machines are fully customizable to meet the unique requirements of each customer, ensuring optimal performance and efficiency.

- Technical Support:Our dedicated technical support team provides prompt assistance and ensures smooth operation throughout the product lifecycle.

Contact Us

RUILIAN, an expert manufacturer and supplier with numerous long stretches of creation experience in fuel tank seam welding customization machine, contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.