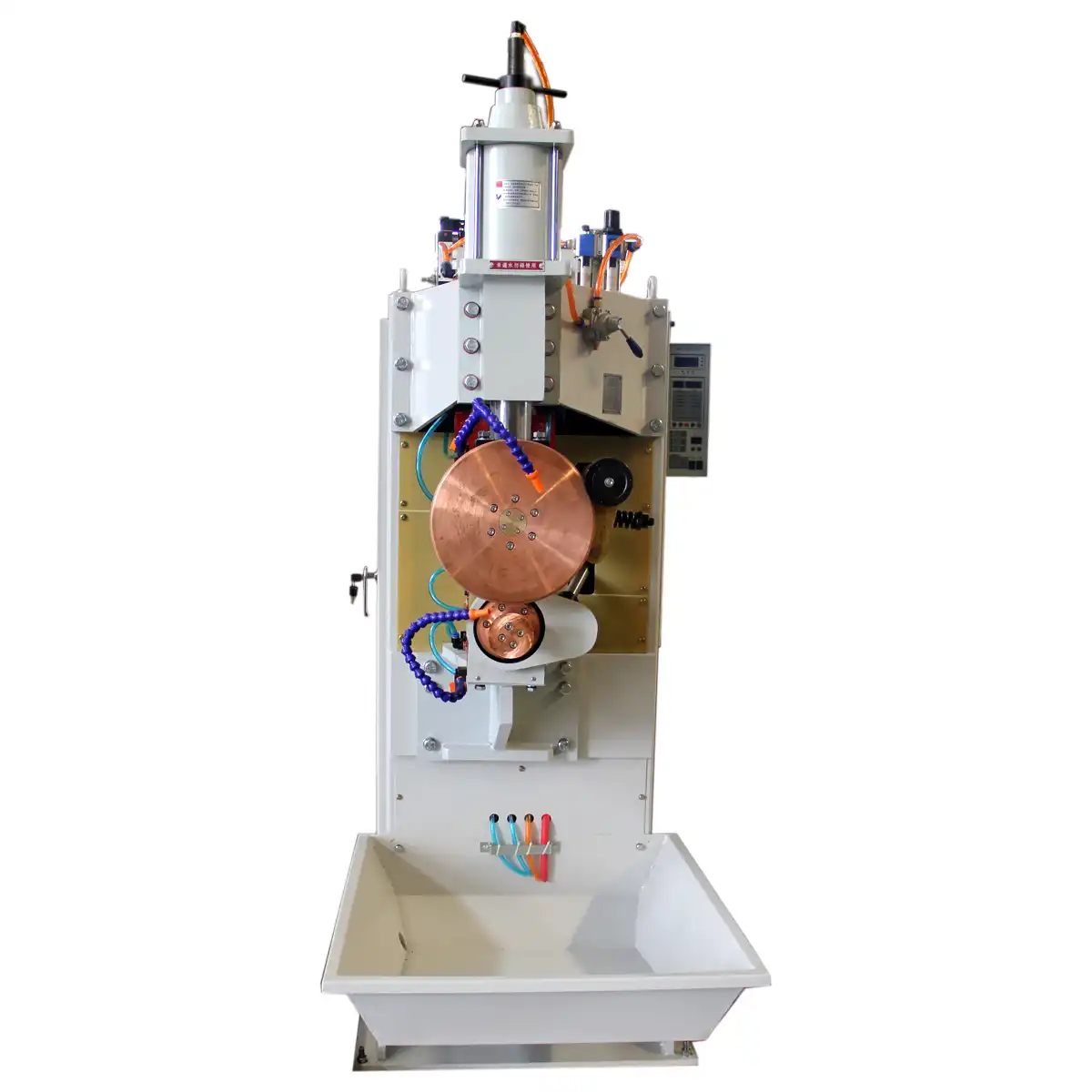

What is Transversal Seam Welder?

The transversal seam welder represents a pinnacle of welding technology, offering precision and efficiency in welding various materials across industries. Engineered with advanced features and robust construction, it stands as a versatile solution for joining metal components with utmost accuracy and reliability. Whether used in automotive, aerospace, or manufacturing sectors, the product ensures seamless welds and enhances production efficiency.

Technical Parameters:

| Parameters | Specifications |

|---|---|

| Welding Speed | 2-6 m/min |

| Welding Thickness | 0.5-3mm |

| Power Supply Voltage | 220V/380V 50/60 HZ |

| Rated Power | 50-150kW |

| Cooling Method | Water Cooling |

| Control System | PLC Control |

| Welding Throat Depth | 200-1000mm |

| Machine Weight | 1500-3000 kg |

| Dimensions (LWH) | Customizable |

Product Features:

- Versatility:Capable of welding a wide range of materials, including steel, aluminum, and stainless steel, with consistent quality.

- Adjustable Parameters: Flexible welding parameters allow customization according to material thickness, joint geometry, and desired weld quality.

- High Precision: Advanced control systems ensure precise electrode movement and alignment, resulting in accurate welds.

- Efficiency: Rapid welding speeds and automated processes streamline production, reducing cycle times and increasing productivity.

- User-Friendly Interface: Intuitive controls and a user-friendly interface make operation straightforward, minimizing training requirements.

- Reliability:Robust construction and quality components ensure long-term reliability and minimal downtime.

Application Fields:

- Automotive Industry: Utilized in the creation of vehicle parts, for example, chassis, body boards, and exhaust frameworks, guaranteeing structural integrity and life span.

- Aerospace Sector: Critical for manufacturing aircraft components, including fuselages, wings, and engine parts, where precision and reliability are paramount.

- Manufacturing Sector:Used to ensure great welds and structural integrity in an assortment of assembling processes, including the fabrication of pressure vessels, stockpiling tanks, and primary parts.

Quality Control and Safety Standards:

- ISO Certification:Manufactured in compliance with ISO quality management standards, ensuring consistent quality and performance.

- Safety Features: Equipped with safety features such as emergency stop buttons and safety guards to protect operators from hazards.

- Quality Assurance:Rigorous quality control measures at every stage of production guarantee superior weld quality and reliability.

Why Choose Us?

- Industry Experience: Since we have been producing welding hardware for a lot of time, we have the skill important to give inventive and reliable arrangements.

- Customization: Our machines are fully customizable to meet the unique requirements of each customer, ensuring optimal performance and efficiency.

- Quality Assurance: We adhere to stringent quality control standards to guarantee the highest level of quality and reliability in our products.

- Technical Support: Throughout the product lifecycle, our dedicated technical support team provides prompt assistance and ensures smooth operation.

Contact Us

transversal seam welder from RUILIAN embodies precision, reliability, and versatility, making it the preferred choice for industries worldwide. Contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.