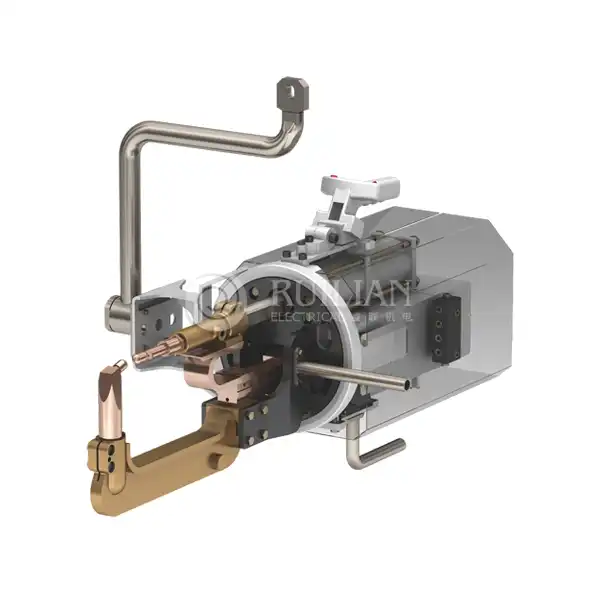

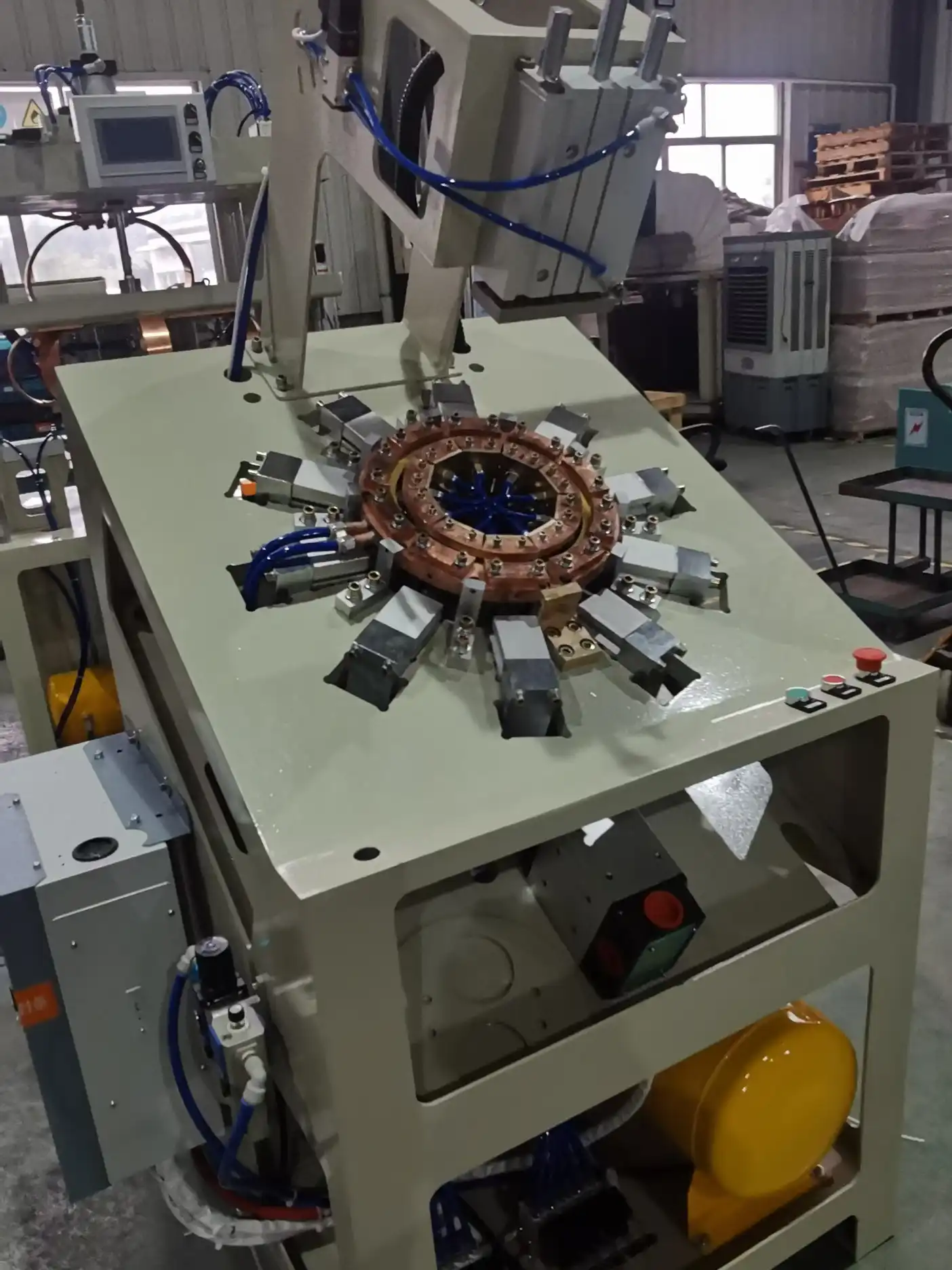

What is Table Heating Plate Spot Welding Machine?

The Table Heating Plate Spot Welding Machine stands as an epitome of precision engineering, designed to cater to the demands of modern industrial welding requirements. Crafted to ensure seamless and efficient spot welding operations, this machine embodies innovation and reliability. With a focus on delivering superior performance and versatility, it serves as an indispensable asset across various industries.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Power Supply | 220V/380V , 50HZ/60HZ |

| Rated Capacity | 50 KVA |

| Max. Short Circuit Current | 15 kA |

| Electrode Stroke | 10 - 30mm |

| Welding Thickness | 0.5-2 mm (Stainless Steel) |

| Welding Diameter | Φ200-Φ1500mm |

| Cooling Method | Water Cooling |

| Control System | PLC Control |

| Dimension (L×W×H) | According to product specifications |

| Weight | According to product specifications |

Product Features:

- High Precision Welding: Offers precise control over welding parameters, ensuring consistent spot welds with minimal variation.

- Versatile Application: Obliges many materials and thicknesses, making it appropriate for different modern applications.

- Efficient Cooling System: Incorporates an efficient water cooling system to maintain optimal operating temperatures, prolonging Table Heating Plate Spot Welding Machine lifespan.

- User-friendly Interface: Equipped with a user-friendly PLC control system, facilitating easy operation and parameter adjustment.

- Robust Construction: Engineered with durable materials and components, guaranteeing long-term reliability and stability.

Application Fields:

- Automotive Industry: Ideal for manufacturing automotive components such as exhaust systems, chassis, and body panels.

- Electronics Manufacturing: Used in the production of electronic enclosures, circuit boards, and battery packs.

- Metal Fabrication: Widely employed in metal fabrication processes for creating joints in sheet metal assemblies.

- Aerospace Sector: Trusted for welding critical components in aircraft structures, ensuring structural integrity and reliability.

- Medical Equipment: Applied in the assembly of medical devices and equipment, meeting stringent quality and regulatory standards.

Quality Control and Safety Standards:

- ISO Compliance: Manufactured in accordance with ISO quality standards to ensure product consistency and reliability.

- CE Certification: Meets CE safety requirements, guaranteeing compliance with European safety regulations.

- Performance Testing: Undergoes rigorous performance testing and quality inspections to validate functionality and durability.

Why Choose Us?

- Innovative Solutions: We pride ourselves on offering cutting-edge welding solutions tailored to meet evolving industry demands.

- Exceptional Quality:Our obligation to quality is reflected in each part of our items, guaranteeing predominant execution and dependability.

- Customer-centric Approach: We prioritize customer satisfaction, striving to exceed expectations through personalized service and support.

- Technical Expertise: Backed by a team of skilled engineers and technicians, we possess the expertise to tackle complex welding challenges effectively.

- Continuous Improvement: We are devoted to constant improvement, utilizing input and advancement to upgrade our items and administrations.

About RUILIAN:

RUILIAN is a renowned manufacturer and supplier with years of experience in producing Table Heating Plate Spot Welding Machine,Contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.