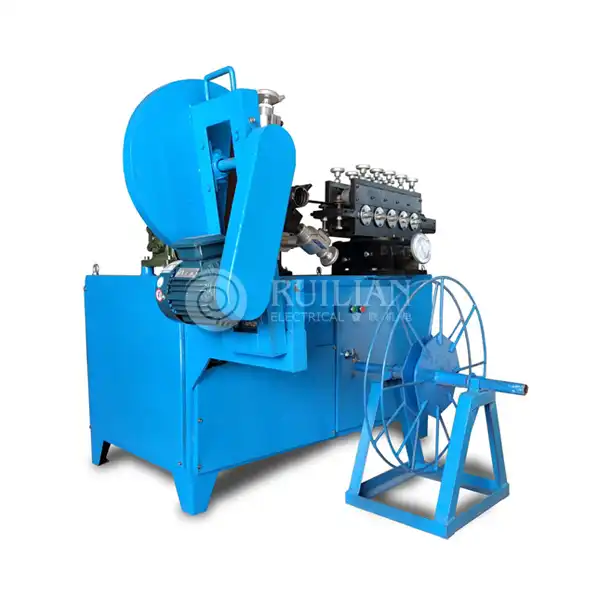

What is Heavy Duty Rolling Machine?

In the domain of modern assembling, accuracy and effectiveness are vital. The Heavy Duty Rolling Machine remains as a demonstration of mechanical ability, offering unmatched execution in metal shaping cycles. From forming huge sheets of metal to creating complex parts with most extreme precision, this machine reclassifies the principles of efficiency and quality in assembling tasks around the world.

Technical Parameters

| Parameter | Specification |

|---|---|

| Maximum Rolling Thickness | Up to 1.5mm |

| Rolling Width | 1000mm - 2000mm |

| Rolling Speed | Adjustable, up to 10m/min |

| Main Motor Power | 5kW - 20kW |

| Hydraulic System | Pressure: 25MPa |

Product Features

1. Constructive Stability: The Heavy Duty Rolling Machine is built to last in tough industrial environments with high-quality materials and precision engineering.

2. Application Options: From thick steel plates to sensitive composites, this machine obliges many materials, making it appropriate for assorted assembling needs.

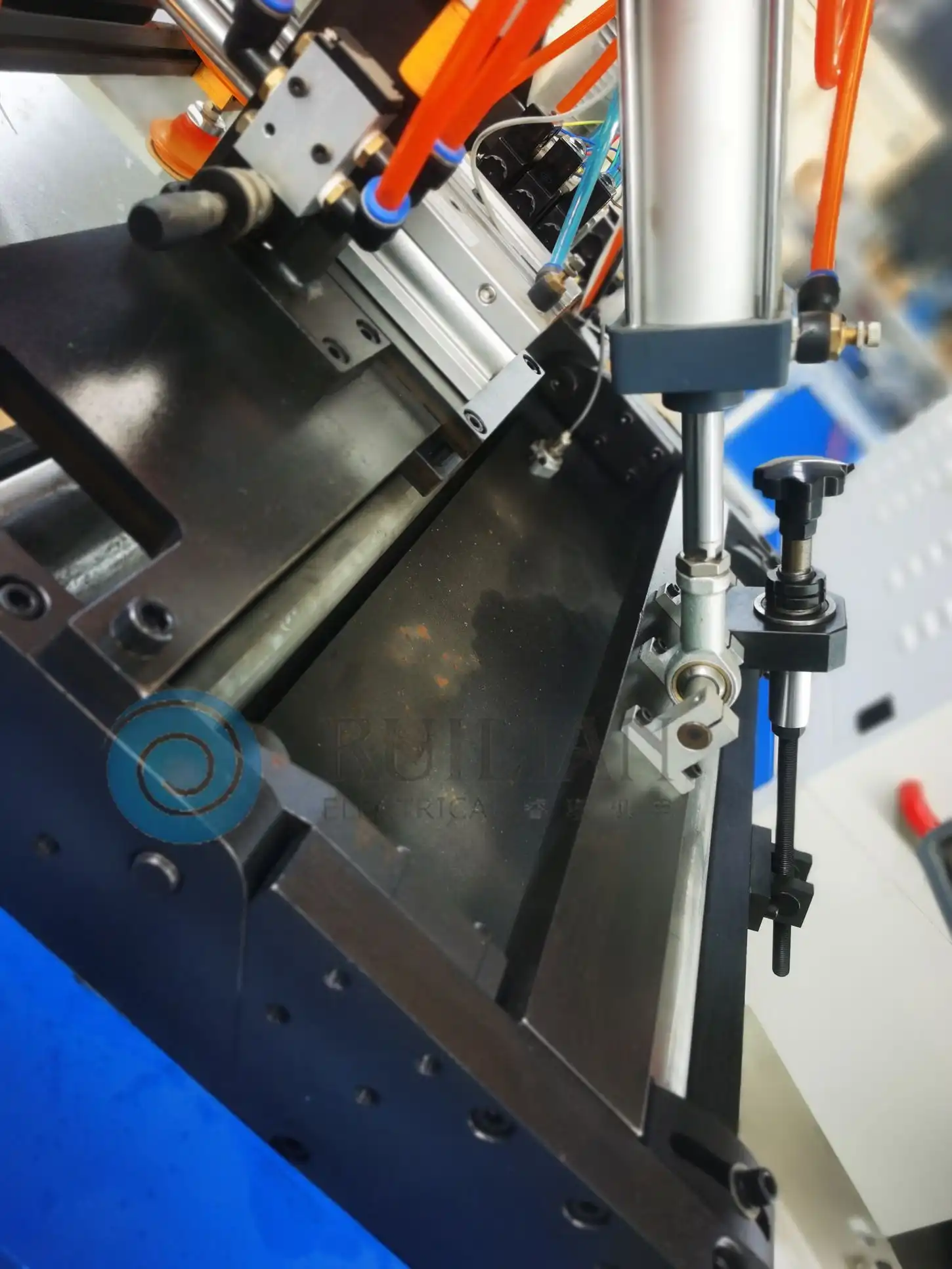

3. High level Control Framework: Furnished with natural controls and easy to use interfaces, administrators can undoubtedly screen and change boundaries for ideal execution.

4. High Accuracy: With exact roller arrangement and tension control, the machine guarantees predictable outcomes with negligible deviations, fulfilling the strictest quality guidelines.

Technical Advantages

1. High Efficiency: The machine's powerful motor and hydraulic system deliver swift and efficient rolling, reducing production time and costs.

2. Adjustable Settings: Customized for different applications, the machine offers adaptable settings to oblige explicit material sorts and thicknesses.

3. Energy Proficiency: Regardless of its strong presentation, the machine is intended for energy effectiveness, limiting power utilization and natural effect.

4. Low Support: Designed for dependability, the machine requires negligible support, bringing about continuous creation and lower in general working expenses.

Application Fields

1. Auto Industry: The machine is essential in shaping vehicle metal parts, including chassis components and body panels.

2. Shipbuilding: The machine is useful for making large structures and hull parts and helps build ships that are safe to sail on.

3. Aerospace: In the aviation area, accuracy is foremost. The machine works with the creation of perplexing parts for airplane and space apparatus.

4. Construction: From primary steel pillars to structural components, the round air duct is crucial in the development business, empowering the manufacture of specially crafted metal parts.

Quality Control and Safety Standards

1. ISO 9001 Certification: The coil welding complies with international quality standards, guaranteeing superior performance and reliability.

2. Wellbeing Guidelines: Complying with severe security guidelines, the machine focuses on administrator wellbeing through strong plan and inherent wellbeing highlights.

Why Choose Us?

1. Industry Expertise: With years of experience in manufacturing heavy-duty industrial machinery, we possess unparalleled expertise and insight into customer needs.

2. Innovation and Research: Our commitment to innovation drives the development of cutting-edge solutions that empower businesses to thrive in a competitive market.

3. Quality Assurance: From design to production, our rigorous quality control measures ensure that every product meets the highest standards of performance and reliability.

4. Customer-Centric Approach: We prioritize customer satisfaction above all else, offering tailored solutions, responsive support, and transparent communication at every step of the journey.

Contact Us

As a professional Heavy Duty Rolling Machine manufacturer and supplier with years of experience, RUILIAN is your trusted partner in achieving manufacturing excellence. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.