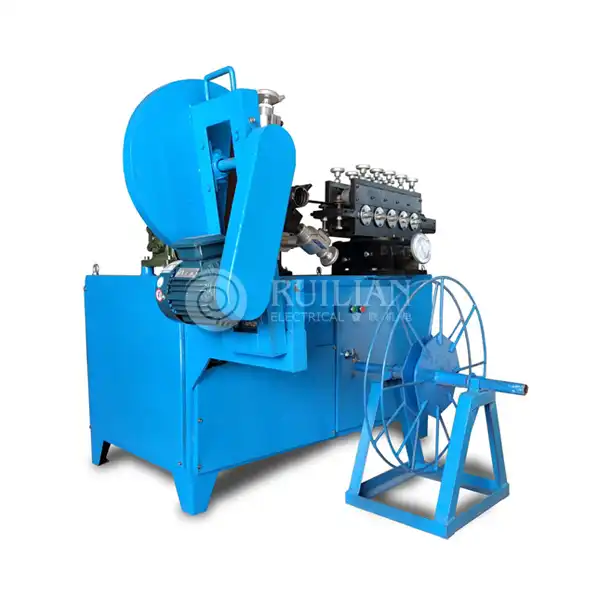

What is Duct Sealing Shaper Machine?

The Duct Sealing Shaper Machine addresses the encapsulation of advancement and proficiency in the field of air conduit creation. This state of the art machine is intended to smooth out the most common way of introducing elastic rings on air channels, upgrading efficiency and guaranteeing accuracy in each activity. With its trend setting innovation and vigorous development, the product sets another norm for execution and unwavering quality in the central air industry.

Technical Parameters

| Parameter | Specification |

|---|---|

| Duct Diameter Range | 80 - 1250mm |

| Rubber ring processing thickness | 0.4mm - 1.0mm |

| Production Capacity | Adjustable |

| Power Supply | Customizable |

| Weight | Variable |

| Dimensions (LxWxH) | Customizable |

Working Principle

1. The air duct is positioned on the machine's platform, ready for the rubber ring installation process.

2. The machine's feeder mechanism feeds the rubber ring into the designated groove of the air duct.

3. As the air duct progresses through the Duct Sealing Shaper Machine, the rubber ring is securely installed around its circumference.

4. Advanced sensors and actuators ensure precise alignment and tension control, resulting in consistent and reliable sealing.

Product Features

1. Automated Operation: Fully automated process reduces labor requirements and increases efficiency.

2. Adjustable Settings: Flexible parameters allow for customization according to duct size and rubber ring thickness.

3. High-Speed Production: Rapid installation process minimizes production time and maximizes throughput.

4. Precision Engineering: Precision components ensure accurate positioning and alignment of rubber rings.

5. User-Friendly Interface: Intuitive controls and user-friendly interface make operation simple and efficient.

Technical Advantages

1. High level Taking care of Framework: Cutting edge feeder system guarantees smooth and dependable conveyance of elastic rings.

2. Accuracy Sensors: High-precision sensors screen each phase of the establishment interaction, guaranteeing ideal outcomes.

3. Hearty Development: Rock solid edge and parts give toughness and long haul unwavering quality.

4. Energy Effectiveness: Streamlined plan limits energy utilization without forfeiting execution.

5. Customization Choices: Fitted arrangements accessible to meet explicit prerequisites and application needs.

Application Fields

1. Air conditioning Industry: Fundamental for fixing air pipes in private, business, and modern central air frameworks.

2. Development Area: Utilized in the development of structures, stockrooms, and different designs with ventilation frameworks.

3. Car Assembling: Utilized in the creation of air conduits for vehicles, guaranteeing impermeable seals and productive wind stream.

4. Aviation Applications: Basic for keeping up with pressure trustworthiness in airplane ventilation and ecological control frameworks.

Why Choose RUILIAN?

RUILIAN stands as a trusted manufacturer and supplier of the air duct seal, boasting extensive experience in production and innovation. Our commitment to excellence is evident in our independent research and development initiatives, as well as our dedication to providing tailored solutions to meet the unique needs of our customers. With a focus on self-production and sales, we offer batch orders and customized services to ensure customer satisfaction and project success.

Contact Us

We are Duct Sealing Shaper Machine manufacturer and supplier, for inquiries or orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.