What is 2 Roll Plate Bending Machine?

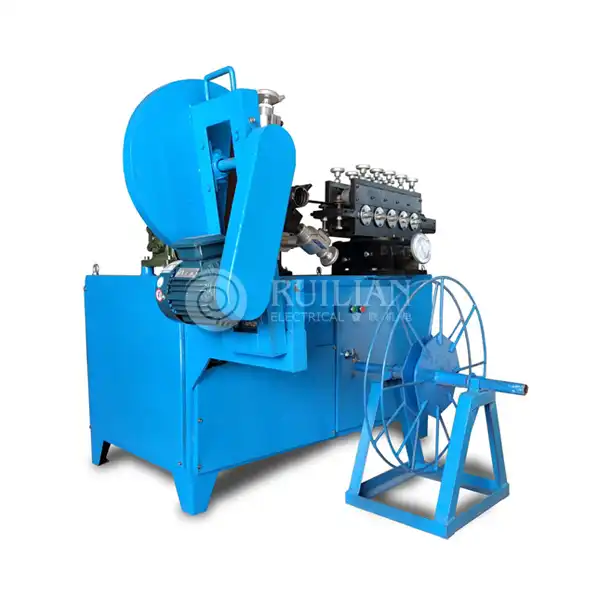

The 2 Roll Plate Bending Machine remains as a demonstration of accuracy designing, offering unmatched proficiency and dependability in plate twisting tasks. This machine addresses the pinnacle of innovation in the field and is designed to meet the various requirements of modern applications.

Built for demanding workshops and fabrication shops, our 2 Roll Plate Bending Machines deliver accurate and efficient metal forming for a wide range of applications.

Technical Parameters

| Parameter | Specification |

|---|---|

| Bending Length | Customizable |

| Bending Thickness | 0.4mm - 1.5mm |

| Rolling Speed | Adjustable |

| Maximum roll length | 2m |

| Maximum coil diameter | 1250mm |

| Weight | Variable |

| Dimensions (LxWxH) | Customizable |

Product Features

High Precision: Equipped with advanced CNC controls for accurate bending down to the micrometer.

Versatile Bending: Capable of handling a wide range of material thicknesses and widths, ensuring flexibility in production.

Robust Construction: Built with durable materials to withstand heavy industrial use, minimizing downtime.

User-Friendly Interface: Intuitive control panel for easy operation and programming, reducing training time.

Energy Efficiency: Optimized for lower energy consumption, contributing to cost savings over time.

Automatic Functions: Features like automatic pre-bending and end-forming enhance productivity.

Application Fields

Steel Construction: 2 Roll Plate Bending Machine is ideal for bending beams, channels, and angles for structural components.

Shipbuilding: Perfect for forming hull plates and structural components with high precision.

Aerospace: Used for crafting parts that require exact curvature specifications.

Pressure Vessels: Essential for manufacturing curved shells and heads for boilers and tanks.

Automotive: For producing chassis components and body parts with complex shapes.

Quality Control and Safety Standards

CE Certified: Meets European safety, health, and environmental protection standards.

ISO 9001: Quality management system certification, ensuring consistent quality.

After-Sales Service

1. Specialized Help: Committed help groups give help establishment, preparing, and investigating.

2. Supply of Spare Parts: Extensive stock of extra parts guarantees brief conveyance and negligible free time.

3. Guarantee Inclusion: Liberal guarantee terms give inner harmony and security against assembling deserts.

Why Choose RUILIAN?

Innovation: Continuous R&D ensures our machines are at the forefront of technology.

Customization: Tailored solutions to meet specific customer needs.

Reliability: Proven track record with global clients, backed by robust after-sales support.

Global Presence: Extensive network of service centers and dealers worldwide.

Sustainability: Commitment to eco-friendly manufacturing processes.

Contact Us

We are manufacturer and supplier of 2 Roll Plate Bending Machine,For inquiries or orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.

Tel: 18220830128

15029861551

WeChat: ston-ren

Whatsapp:+86 18220830128