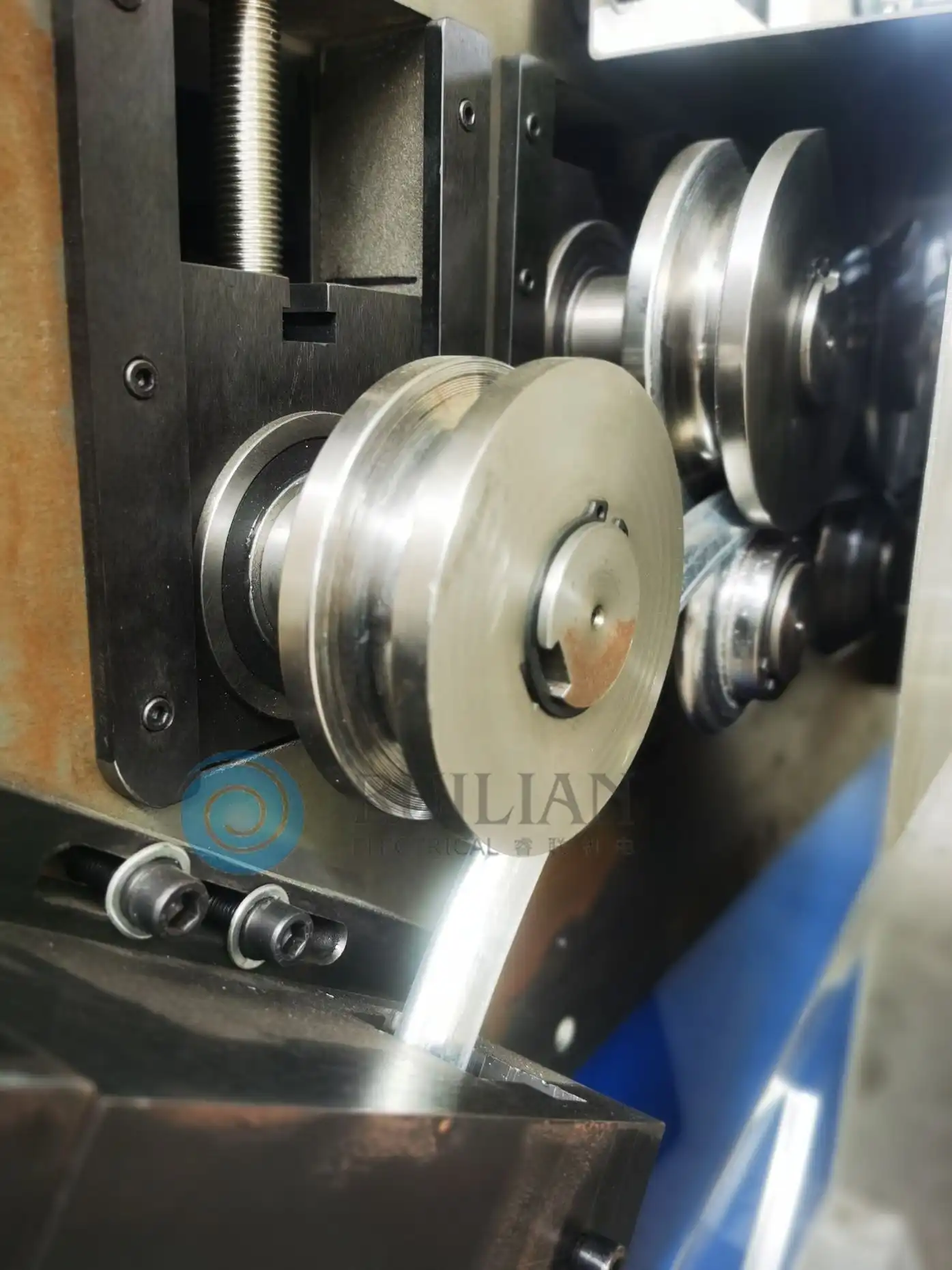

What is Flange Punching Machine?

In the realm of industrial manufacturing, precision and efficiency are paramount. The Flange Punching Machine stands as a pinnacle of technological innovation, offering unmatched performance in the fabrication of flanges for various applications. From enhancing structural integrity to ensuring seamless connections, this machine redefines the standards of precision and reliability in flange production, catering to the diverse needs of industries worldwide.

Why Choose Our Flange Punching Machines?

Proven Track Record: Decades of experience serving demanding industries, with numerous success stories

Continuous Innovation: R&D investments focused on efficiency, precision, and sustainability

ISO 9001:2015 Certified: Unwavering commitment to quality, reliability, and customer satisfaction

Technical Parameters

| Parameter | Specification |

|---|---|

| Maximum Flange Diameter | Up to 1500mm |

| Punching Thickness | 1mm - 3mm |

| Punching Speed | Adjustable, up to 30 strokes/min |

| Motor Power | 5.5kW - 15kW |

| Control System | PLC Control |

Product Features

| Key Advantage | Description |

|---|---|

| Unparalleled Precision | ±0.05 mm tolerance ensures accurate, burr-free holes for critical applications |

| High-Throughput Capability | Up to 300 punches per minute, minimizing production downtime |

| Adaptability | Compatible with various flange sizes, materials, and hole patterns |

Application Fields

Automotive Industry:

Manufacturing of car chassis components, exhaust systems, and engine mounts where flanges are used for connections.

Aerospace:

Production of aircraft structural components, where high precision and material integrity are critical.

Construction:

Fabrication of steel structures, including beams and columns that require flanged connections for assembly.

Energy Sector:

For pipelines, wind turbines, and solar panel mounts, where flanges connect sections or secure parts.

Shipbuilding:

Creating parts for ship hulls, deck fittings, and other marine applications requiring robust flange connections.

Certification

ISO 9001:2015: Quality management system certification ensuring consistent performance and continuous improvement

CE Marking: Conformity to EU health, safety, and environmental protection standards

UL (Underwriters Laboratories) and ETL (Intertek) Listings: Compliance with North American safety standards for industrial equipment

Why Choose Us?

1.Industry Expertise: With years of experience in manufacturing precision machinery, we bring unparalleled expertise and insight to flange punching solutions.

2.Innovation and Technology: Our commitment to innovation drives the development of cutting-edge solutions that empower businesses to excel in their respective industries.

3.Quality Assurance: Rigorous quality control measures and attention to detail ensure that our machines deliver unparalleled performance and reliability.

4.Customer-Centric Approach: We prioritize customer satisfaction, offering personalized solutions, responsive support, and seamless service experiences.

Contact Us

As a professional Flange Punching Machine manufacturer and supplier with years of experience, RUILIAN is your trusted partner in achieving manufacturing excellence. For inquiries and orders, please contact us at ry@china-ruilian.cn and hm@china-ruilian.cn.