What is Water Heater Shell Welding Machine?

With its cutting-edge technology and precise engineering, the Water Heater Shell Welding Machine is a beacon of innovation that has changed the manufacturing landscape for water heater shells. This cutting-edge machine is explicitly intended to smooth out and improve the welding system of water radiator shells, guaranteeing consistent incorporation and remarkable quality.

Technical Parameters

| Parameter | Specification |

|---|---|

| Welding Method | Resistance Welding |

| Welding Speed | 3 - 12m/min |

| Welding Thickness | 0.4 - 1.0 mm |

| Power Supply | 220V/380V , 50/60Hz |

| Welding Diameter | 300 - 500 mm |

| Motor Power | 50 kW |

| Control System | PLC Control |

| Dimensions (L×W×H) | 3500×1800×2000 mm |

| Weight | 2000 kg |

Item Highlights

1.The MIG/MAG Welding Method: Utilizes progressed MIG/MAG welding processes for superior grade, proficient welds.

2.Variable Speed Control: Customizable welding rate to oblige different material thicknesses and creation prerequisites.

3.Advanced Control Board: Easy to use interface for simple activity and observing of welding boundaries.

4.Great Welding Firearm: Outfitted with a solid and exact welding weapon for steady and dependable execution.

5.Process for Automatic Welding: Work that is completely automated is less labor-intensive and guarantees consistent weld quality.

6.Safety Equipment: Consolidates wellbeing interlocks and crisis stop buttons to guarantee administrator security during activity.

Application Fields

1.Producing Heaters for the Water: Essential for the production of a variety of water heaters, including heat pump, tankless, and storage models.

2.Applications in Industry: Used to weld metal shells for boilers, pressure vessels, and storage tanks in industrial settings.

3.Sector of Renewable Energy: Assumes a urgent part in the manufacture of parts for sun powered water warming frameworks and geothermal intensity siphons.

4.Business Framework: Utilized for hot water supply systems in the construction of hotels, hospitals, and commercial buildings.

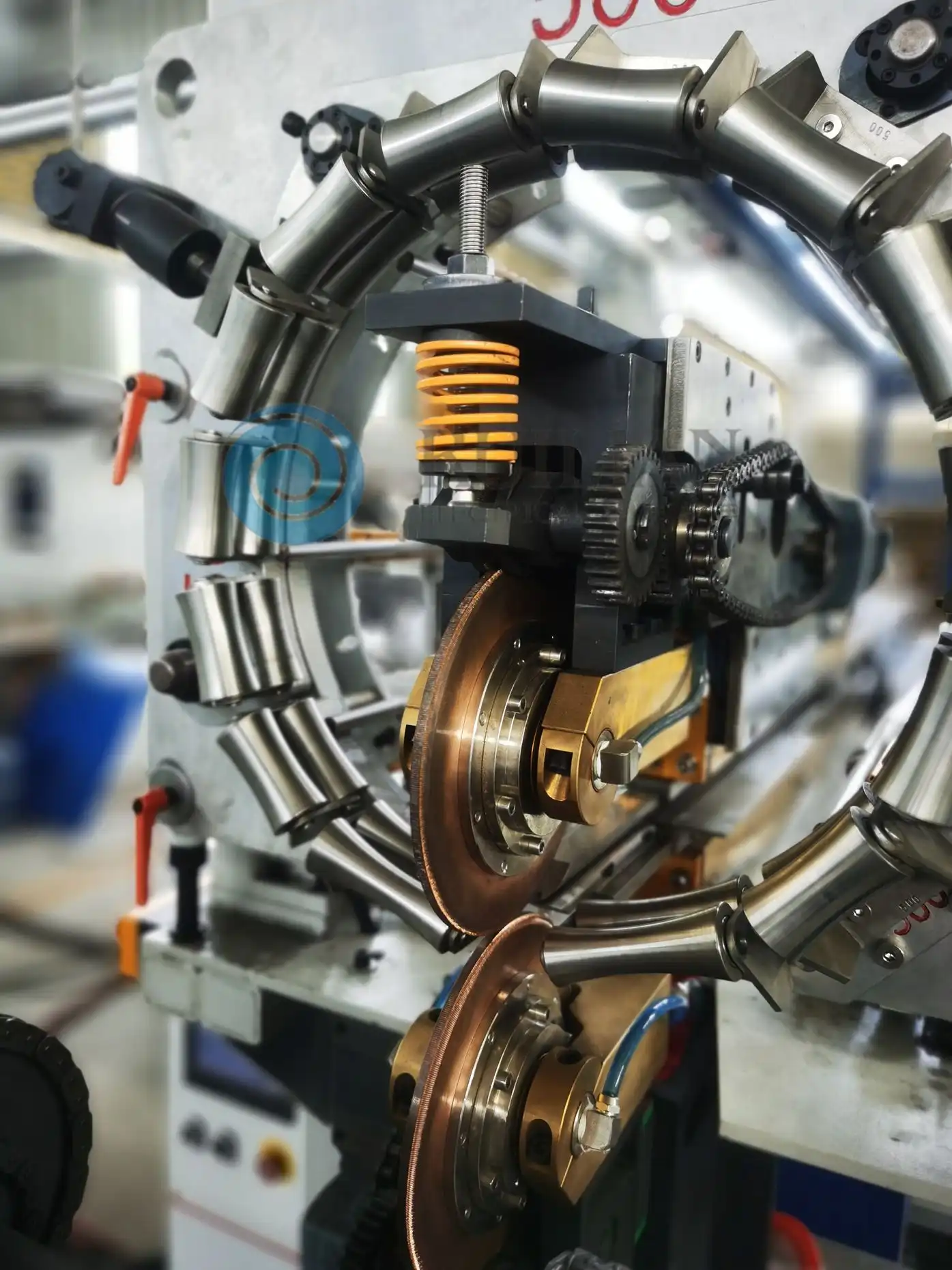

Equipment Composition

1.Head of Welding: Controls the welding process and houses the welding torch.

2.Bracing Framework: During welding, it holds the components of the water heater shell in place.

3.Power Supply Unit: Gives the important electrical capacity to welding activities.

4.Wire Feeder: Continuously provides welding wire to the welding gun.

5.Panel control: Interface for setting and observing welding boundaries.

Quality Control and Safety Standards

1.ISO Affirmation: Consistence with global quality administration guidelines guarantees steady quality and consumer loyalty.

2.Safety Equipment: Joining of security interlocks, crisis stop buttons, and defensive fenced in areas to forestall mishaps and guarantee administrator wellbeing.

3.Quality Control: Thorough testing and review methods all through the assembling system to keep up with high item quality and dependability.

4.Documentation: Keep up with itemized records of creation cycles and quality control measures for recognizability and responsibility.

5.Continual Development: Obligation to ceaseless improvement drives to upgrade item quality, effectiveness, and security guidelines.

Why Choose RUILIAN?

1.Industry Administration: With a proven track record of providing innovative solutions and superior products, RUILIAN is a respected leader in the welding equipment industry.

2. Technical Knowledge: Upheld by a group of gifted designers and specialists, RUILIAN offers unrivaled specialized skill and backing to clients.

3.Quality Affirmation: RUILIAN ensures that special welding machine meet the highest performance and durability standards by placing an emphasis on quality and dependability.

4. Approach centered on the customer: Customer satisfaction is a top priority for RUILIAN, which provides individualized service, prompt support, and individualized solutions to meet each customer's needs.

5.Global Presence: RUILIAN serves customers all over the world by providing prompt and effective solutions to their welding requirements through its global network of partners and distributors.

Contact Us

RUILIAN is a leading Water Heater Shell Welding Machine manufacturer and supplier. For requests and orders, kindly get in touch with us at ry@china-ruilian.cn and hm@china-ruilian.cn.