What are the benefits of using an air duct rubber ring machine?

In the HVAC industry and beyond, air ducts play a critical role in managing airflow, ensuring heating and cooling systems operate efficiently. One often-overlooked yet essential aspect of ductwork is the airtight seal between duct sections. To achieve this, the Air Duct Rubber Ring Machine is employed. This machine offers precision and efficiency in securing rubber rings around air ducts, creating airtight seals that improve system performance and reduce energy waste. In this blog, we will explore the key benefits of using an air duct rubber ring machine and its relevance in various industries.

Enhanced Sealing Efficiency and Airtightness

One of the primary advantages of using an Air Duct Rubber Ring Machine is the significant boost in efficiency it offers when sealing air ducts. In any ventilation system, rubber rings play a crucial role in creating airtight connections between duct sections. These connections are essential for preventing air leakage, which can lead to reduced energy efficiency and increased operating costs. When air escapes from poorly sealed ducts, not only does it compromise the performance of the HVAC system, but it also forces systems to work harder to maintain desired temperatures, driving up energy bills.

By employing this specialized machine, manufacturers can achieve a secure and tight seal that effectively minimizes air loss. The consistent application of rubber rings ensures that every joint is reliable, maintaining the integrity of the entire ventilation system. Unlike manual methods, which can be prone to inconsistencies and errors, the Air Duct Rubber Ring Machine provides unparalleled precision. It guarantees that each rubber ring is positioned correctly and uniformly across all ducts, which is especially vital in large-scale production environments where hundreds or even thousands of ducts must meet high-quality standards.

Moreover, the tight seals created by this machine significantly reduce the likelihood of gaps or cracks forming in duct connections. Such imperfections can lead to energy losses, inefficiencies, and ultimately affect the comfort of the spaces being ventilated. In industries where airtight ductwork is critical—such as in ventilation systems for commercial buildings, industrial facilities, and marine vessels—this machine proves to be invaluable. By optimizing the sealing process, it ensures that duct systems perform at their highest efficiency while adhering to stringent industry standards. Consequently, investing in an Air Duct Rubber Ring Machine not only improves operational efficiency but also contributes to long-term cost savings and enhanced environmental sustainability.

Increased Productivity and Reduced Labor Costs

A major benefit of the Air Duct Rubber Ring Machine is its ability to automate what would otherwise be a labor-intensive task. Traditionally, applying rubber rings to air ducts involved considerable manual labor, which not only increased the time and effort required for production but also heightened the risk of inconsistency and errors. These imperfections could result in defects that necessitate rework, ultimately delaying project timelines and increasing costs.

By incorporating an automated machine into the production process, manufacturers can significantly enhance their efficiency. The machine facilitates the rapid application of rubber rings, allowing for quicker production cycles and reducing the need for a large workforce. This shift to automation leads to substantial savings in labor costs, enabling companies to allocate resources more effectively. Moreover, as demand for air ducts continues to rise, this increased productivity becomes crucial. Manufacturers can scale up operations to meet market needs without compromising on quality, ensuring that each duct conforms to high standards.

Investing in an Air Duct Rubber Ring Machine not only streamlines operations but also offers long-term financial benefits. While the initial investment may seem significant, the savings accrued from reduced labor expenses, fewer mistakes, and heightened output can quickly offset this cost. Furthermore, the consistent performance of the machine minimizes the likelihood of future repairs and maintenance, adding to the overall cost-effectiveness of this investment.

In summary, the transition to an automated system through the use of an Air Duct Rubber Ring Machine represents a strategic move for manufacturers aiming to enhance their production capabilities. By embracing this technology, companies can improve operational efficiency, reduce costs, and maintain the high-quality standards demanded by the industry, positioning themselves for success in a competitive market.

Versatility and Application in Various Industries

The Air Duct Rubber Ring Machine is not limited to just one industry. Its application spans across multiple sectors, making it a versatile tool for manufacturers that deal with ventilation, heating, cooling, and other air management systems.

HVAC Systems: The Air Duct Rubber Ring Machine plays a vital role across several industries, with its most common application found in HVAC systems. In this sector, airtight ductwork is essential for maintaining system efficiency and performance. The machine ensures that ducts used in heating and cooling systems are properly sealed, effectively preventing energy loss. By achieving optimal sealing, the Air Duct Rubber Ring Machine not only enhances the overall efficiency of HVAC systems but also contributes to reduced operational costs for end users.

Home Appliance Manufacturing: This machine is crucial in the manufacturing of home appliances. Many household devices, such as dryers and kitchen exhaust systems, rely on effective air ducts to operate efficiently. The rubber rings applied by this machine ensure that these ducts are well-sealed, which is pivotal for the proper functioning of these appliances. A well-sealed duct minimizes airflow resistance, thus improving energy consumption and enhancing the performance of the appliances.

Marine Vessels and Aerospace: The Air Duct Rubber Ring Machine is indispensable in high-demand environments like marine vessels and aerospace systems. In these industries, maintaining airtight ducting is critical for ensuring air pressure stability and overall safety. The precision and reliability offered by the machine make it a key component in producing ductwork that meets rigorous standards for performance and safety.

Whether used in large-scale HVAC systems or specialized environments like aerospace, the Air Duct Rubber Ring Machine guarantees consistency, reliability, and durability across all ducting applications.

Conclusion

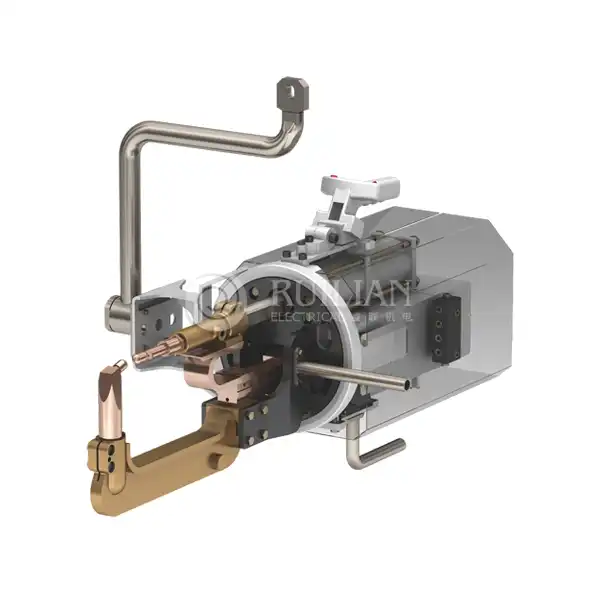

RUILIAN stands as a trusted manufacturer and supplier of the air duct seal, boasting extensive experience in production and innovation. If you're looking for high-quality air duct fabrication equipment, including the Air Duct Rubber Ring Machine, RUILIAN offers reliable solutions for all your needs. Contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com for more information.

References

1. Shaanxi RUILIAN Seam Welding Equipment Co., Ltd. - Air Duct Fabrication Machines

2. HVAC Duct Systems: Importance of Airtightness – Industry Insights

3. Automation in Duct Manufacturing – Engineering Journal

4. Energy Efficiency and Duct Sealing – Technical HVAC Publications

5. Applications of Rubber Rings in HVAC and Other Industries – Manufacturing Case Studies