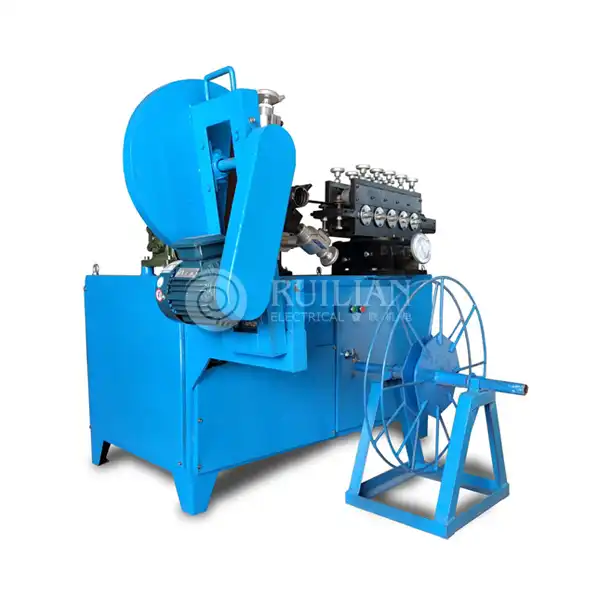

As we explore the benefits of automated welding, we'll focus on how these machines, particularly the Steel Drum Automatic Welding Machine, are transforming industries like ventilation engineering, home appliance manufacturing, aerospace, and marine vessel production.

Enhanced Precision and Consistency in Welding Operations

One of the most significant advantages of automated welding machines is the unmatched precision and consistency they bring to the welding process. Unlike manual welding, which is subject to variations due to human factors such as fatigue, skill level, or environmental conditions, automated systems operate with remarkable consistency, ensuring that each weld is executed with high accuracy. This level of precision is particularly critical in industries where weld quality directly impacts the product’s performance, safety, and reliability, such as aerospace, automotive, and marine vessel construction.

For example, automated machines like the Steel Drum Automatic Welding Machine are designed to follow specific parameters meticulously. These machines are programmed to execute welds based on predetermined specifications, which means every weld is completed with the same level of precision from start to finish. This uniformity is essential when working with materials and structures where even the slightest variation in weld quality can lead to failure or significant operational issues.

In addition to precision, automated welding machines come equipped with advanced sensors and control systems that can monitor and adjust the welding process in real-time. This dynamic capability allows them to produce consistent, high-quality welds across various materials and thicknesses. Achieving this level of accuracy manually would be time-consuming and difficult, particularly when working with complex geometries or hard-to-reach areas.

Furthermore, automated systems help reduce human error, leading to fewer defects and a more efficient production process. This results in stronger, more durable welds and ultimately higher-quality products, which is particularly important in industries where safety and performance standards are non-negotiable. As a result, automated welding machines offer a clear edge over manual methods, improving both the quality and efficiency of manufacturing processes.

Increased Productivity and Efficiency in Manufacturing Processes

Automated welding machines significantly boost productivity and efficiency in manufacturing processes. These machines can operate continuously for extended periods without the need for breaks, unlike human welders who require regular rest periods. This continuous operation translates to higher output and faster production cycles.

The Steel Drum Automatic Welding Machine and automatic spot welding machine, for example, can perform welding tasks at speeds that far exceed manual welding capabilities. It can seamlessly weld drum bodies of various sizes and materials, maintaining high-speed operation without compromising on quality. This increased speed and efficiency are particularly beneficial in industries with high-volume production requirements, such as home appliance manufacturing.

Furthermore, automated welding machines minimize the time required for setup and changeovers between different welding tasks. With pre-programmed settings for various welding parameters, these machines can swiftly adapt to different product specifications, reducing downtime and increasing overall production efficiency.

Another aspect of increased productivity is the reduction in material waste. Automated welding machines, with their precise control over weld parameters, optimize material usage, resulting in less overuse of welding materials and reduced scrap rates. This efficiency not only improves productivity but also contributes to cost savings and more sustainable manufacturing practices.

Enhanced Safety and Improved Working Conditions for Operators

Safety is a paramount concern in any welding operation, and automated welding machines offer significant improvements in this area. By minimizing direct human involvement in the welding process, these machines reduce the risk of injuries associated with manual welding, such as exposure to intense heat, harmful fumes, and bright light.

The Steel Drum Automatic Welding Machine, for instance, incorporates safety features like protective enclosures and automated shut-off mechanisms, ensuring operator safety during operation. These safety measures allow operators to monitor the welding process from a safe distance, reducing their exposure to potential hazards.

Moreover, automated welding machines contribute to improved working conditions by reducing the physical strain on workers. Manual welding often involves awkward positions and repetitive motions that can lead to musculoskeletal disorders over time. By automating these tasks, the physical burden on workers is significantly reduced, leading to better ergonomics and improved occupational health.

The reduction in direct exposure to welding fumes and gases is another crucial safety advantage. Automated welding systems often include advanced fume extraction systems that efficiently remove harmful particulates from the air, creating a healthier work environment. This improvement in air quality is particularly beneficial in enclosed spaces or when working with materials that produce toxic fumes.

Additionally, the use of automated welding machines allows for better control over the welding environment. Factors like temperature, humidity, and airflow can be more precisely regulated in automated setups, further enhancing safety and weld quality.

In conclusion, the advantages of using automated welding machines over manual methods are multifaceted and significant. From enhanced precision and consistency to increased productivity and improved safety, these machines are transforming the welding industry. The Steel Drum Automatic Welding Machine exemplifies these benefits, offering a solution that meets the demanding requirements of modern manufacturing processes.

As industries continue to evolve and face new challenges, the role of automated welding machines in ensuring quality, efficiency, and safety will only grow. For businesses looking to stay competitive and meet the highest standards of production, investing in automated welding technology is not just an option but a necessity.

If you're interested in exploring how automated welding solutions like the Steel Drum Automatic Welding Machine can benefit your operations, we invite you to reach out to us. Our team at RUILIAN is ready to provide expert guidance and tailored solutions to meet your specific welding needs. Contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com to learn more about our range of automated welding machines, resistance welding machines, and how they can revolutionize your manufacturing processes.