What is an aluminum foil spiral duct machine?

An Aluminum Foil Spiral Duct Machine is an essential tool used in the manufacturing of aluminum spiral ducts, which are widely used in HVAC systems, air conditioning units, and ventilation networks. These machines are designed to form durable and efficient ducts by winding aluminum foil into a spiral shape, which is then used for air transportation, extraction, and ventilation. In this blog, we will explore the function, benefits, and key features of an aluminum foil spiral duct machine, and discuss how this technology is revolutionizing duct production for various industries.

How Does an Aluminum Foil Spiral Duct Machine Work?

The core functionality of an Aluminum Foil Spiral Duct Machine is to take a flat aluminum foil coil and shape it into a spiral duct. The process is highly automated, ensuring high precision and consistency, which is crucial for applications where airflow efficiency and structural integrity are paramount.

The Forming Process

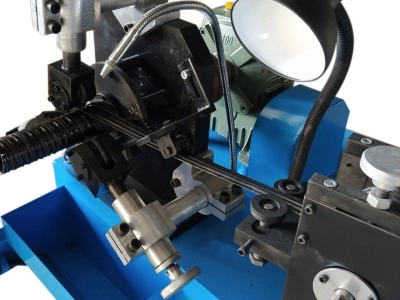

The machine starts by feeding a coil of aluminum foil into a forming unit. The aluminum foil is fed into a set of rollers that gradually shape the material into a tight spiral. The rollers are designed to ensure the aluminum foil is evenly wound, creating a smooth and uniform duct. The tightness and consistency of the spiral are critical for ensuring that the ducts can withstand high-pressure airflow without deforming or leaking.

Seaming and Locking the Spiral

After the aluminum foil has been spiraled into the desired shape, the machine then uses a specialized mechanism to lock the seam, ensuring that the duct retains its spiral form. The seam is an essential part of the process because it prevents the duct from unwinding and helps to maintain its integrity throughout its lifecycle. The machine may also include additional features such as automated cutting, which ensures that the ducts are cut to the required length.

Automatic Control and Precision

Modern Aluminum Foil Spiral Duct Machines are equipped with automatic control systems, allowing operators to set parameters such as the thickness of the foil, the size of the duct, and the speed of the production process. This automation ensures that the finished product meets the required specifications, with minimal human intervention and reduced potential for errors. Additionally, the precision of these machines allows manufacturers to produce ducts with smooth inner and outer surfaces, which is important for reducing friction and improving airflow efficiency in HVAC systems.

What Are the Key Benefits of Using an Aluminum Foil Spiral Duct Machine?

The adoption of Aluminum Foil Spiral Duct Machines offers numerous benefits for manufacturers and end-users alike. These machines provide high efficiency, precision, and versatility, making them a valuable asset in industries that rely on effective air distribution systems.

Enhanced Durability and Strength

Aluminum is a lightweight yet strong material, making it ideal for the production of spiral ducts. The use of an aluminum foil spiral duct machine ensures that each duct produced is both durable and lightweight, making it easier to handle, install, and maintain. The strength of the finished product also ensures that it can withstand the demands of various environmental conditions, including high-pressure airflow and temperature fluctuations.

Improved Airflow Efficiency

One of the key advantages of using spiral ducts is their superior airflow efficiency compared to traditional rectangular ducts. The smooth, continuous spiral shape of the duct allows air to flow more freely, reducing resistance and improving energy efficiency. This is especially important in HVAC systems, where energy savings and optimized airflow are essential for maintaining comfortable indoor environments.

Cost-Effective Production

Using an Aluminum Foil Spiral Duct Machine significantly reduces production costs. These machines automate the duct-forming process, minimizing the need for manual labor and reducing the risk of errors. By increasing production speed and reducing material waste, manufacturers can achieve cost savings that can be passed on to customers. This makes aluminum spiral ducts an attractive option for companies looking to optimize their operations while maintaining high-quality standards.

Versatility in Applications

Aluminum spiral ducts produced by these machines are used in a wide range of industries, including HVAC, automotive, and construction. Their versatility extends beyond just air transportation; they are also commonly used in ventilation systems, exhaust systems, and even in specialized applications where corrosion resistance and lightweight properties are crucial. The ability of Aluminum Foil Spiral Duct Machines to produce ducts in various sizes and thicknesses adds to their appeal in a diverse range of industrial settings.

Why Are Aluminum Foil Spiral Duct Machines Essential for the HVAC Industry?

In the HVAC industry, aluminum spiral ducts are preferred over traditional rectangular ducts for several reasons, including their ease of installation, durability, and ability to maintain consistent airflow. The automation provided by the Aluminum Foil Spiral Duct Machine makes it easier to meet the growing demand for high-quality ducting solutions, especially in commercial and residential building projects.

Faster Installation and Handling

One of the main reasons aluminum spiral ducts are favored in HVAC systems is their ease of installation. The lightweight nature of the ducts makes them easier to handle, and their spiral form ensures a secure fit when connected. Aluminum Foil Spiral Duct Machines ensure that each duct produced is of consistent quality, reducing the potential for installation errors and minimizing time spent on-site.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, which makes aluminum spiral ducts ideal for use in environments where moisture and humidity are prevalent, such as in kitchens, bathrooms, or industrial settings. The precision and durability of the ducts produced by Aluminum Foil Spiral Duct Machines help extend the lifespan of HVAC systems by ensuring that the ducts remain intact and functional over time, even in challenging conditions.

Aesthetic Appeal

The smooth, sleek appearance of aluminum spiral ducts is another advantage, especially in applications where the ducts are visible, such as in modern industrial or commercial buildings. The uniformity of the ducts produced by an Aluminum Foil Spiral Duct Machine ensures that they maintain their aesthetic appeal while also serving as a functional part of the HVAC system.

Conclusion

An Aluminum Foil Spiral Duct Machine is a vital piece of equipment in the production of high-quality aluminum spiral ducts used across various industries, most notably in HVAC systems. These machines automate the duct-forming process, offering benefits such as improved durability, better airflow efficiency, and cost-effective production. As industries continue to prioritize energy efficiency, cost reduction, and product durability, the demand for Aluminum Foil Spiral Duct Machines is likely to grow, making them a crucial tool for modern manufacturing.

If you would like to learn more about Aluminum Foil Spiral Duct Machines or explore other welding and fabrication equipment, feel free to contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com.

References

1. The Evolution of Aluminum Ducting in HVAC Systems.

2. Benefits of Spiral Duct Systems in Ventilation Applications.

3. Automation in Duct Manufacturing: The Role of Advanced Machinery.

4. Improving Energy Efficiency in HVAC with Spiral Ducts.

5. Materials Science: The Advantages of Aluminum in Ductwork Systems.