How to operate a welding machine?

Operating a welding machine requires knowledge, skill, and safety awareness to produce high-quality welds effectively. This guide focuses on the Automatic Drum Body Welding Machine, a sophisticated tool used for welding metal drums. Whether you are new to welding or seeking to enhance your skills, this article provides essential steps and insights to help you operate this equipment confidently and safely.

Knowing the Automatic Drum Body Welding Machine

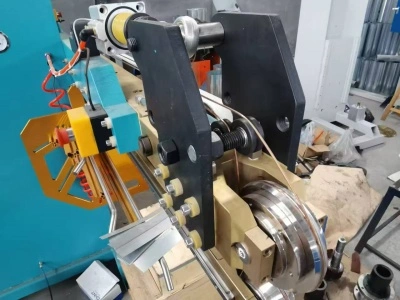

Before delving into operational techniques, it's vital to understand the features and functions of the Automatic Drum Body Welding Machine. This machine is engineered for precision, allowing for the seamless joining of metal components, particularly drum bodies, which are widely used in industries such as storage, transportation, and manufacturing.

The Automatic Drum Body Welding Machine incorporates advanced technology, including automatic feeding systems, programmable welding parameters, and safety features that enhance productivity and reduce human error. By using this machine, operators can achieve uniform welds, improve efficiency, and minimize material wastage.

Preparing to Operate the Welding Machine

Preparation is key to successful welding. Taking the time to set up correctly not only ensures safety but also optimizes the welding process. Here are the essential steps to prepare before operating the Automatic Drum Body Welding Machine:

1. Gather Necessary Equipment

Having the right tools and materials at hand is crucial. Ensure you have:

Welding Machine: Your Automatic Drum Body Welding Machine should be in good working condition.

Protective Gear: Wear appropriate safety gear, including welding gloves, helmets with proper shading, and flame-resistant clothing.

Welding Materials: Ensure you have the correct type and size of metal drum bodies for welding.

2. Inspect the Machine

Before starting, conduct a thorough inspection of the welding machine:

Check Power Supply: Ensure the machine is properly connected to a power source, matching the specified voltage and amperage requirements.

Inspect Cables and Connections: Look for signs of wear or damage on electrical cables and connectors. Replace any faulty parts to avoid accidents.

Examine Safety Features: Verify that all safety mechanisms, such as emergency shut-off switches, are functional.

3. Clean the Work Area

A clean workspace minimizes hazards and enhances efficiency. Clear the area of any flammable materials, debris, or clutter. Adequate ventilation is also necessary to disperse harmful fumes generated during welding.

Operating the Automatic Drum Body Welding Machine

With preparation complete, you are ready to operate the automatic spot welding machine. Here are the steps to ensure a smooth welding process:

1. Set Up the Machine

Before starting the actual welding process, configure the machine settings based on the requirements of your project:

Select Welding Parameters: Depending on the thickness and type of metal, set the voltage, amperage, and welding speed according to the manufacturer's recommendations. Refer to the welding machine's manual for guidance.

2. Secure the Workpieces

To achieve precise welds, the metal drum bodies must be securely positioned. Use clamps or fixtures to hold the pieces together firmly, ensuring no movement occurs during the welding process.

3. Perform the Welding Operation

Now that everything is set, it's time to start welding:

Engage the Machine: Activate the machine according to the manufacturer’s instructions. Many automatic machines will handle the welding process autonomously once parameters are set.

Monitor the Process: Keep a close eye on the welding operation. Look for consistent bead appearance and ensure the machine is functioning as expected.

Handle Adjustments as Needed: If you notice any irregularities in the weld or machine operation, make necessary adjustments immediately. This may include tweaking the settings or addressing any equipment issues.

Safety Considerations While Operating

Safety is paramount when operating any welding machine. Adhering to the following precautions can help prevent accidents and injuries:

Wear Appropriate Protective Gear: Always use safety gear designed for welding. This includes helmets, gloves, and protective clothing that can withstand sparks and heat.

Maintain a Safe Distance: Ensure bystanders maintain a safe distance from the welding area. Use barriers or screens to protect others from UV rays and flying debris.

Be Aware of Fire Hazards: Keep a fire extinguisher nearby and know how to use it. Always have a plan in place for emergency situations.

Post-Welding Procedures

Once the welding operation is complete, it's important to follow specific post-welding procedures:

1. Inspect the Welds

After the welding has cooled, examine the welds for quality and integrity. Look for any signs of defects, such as cracks, voids, or incomplete fusion. Address any issues as necessary to ensure structural integrity.

2. Clean the Work Area

Once inspections are complete, clean the work area again. Remove any metal shavings, scraps, or leftover materials. Proper disposal of welding waste is essential to maintain a safe and tidy environment.

3. Maintain the Equipment

Regular maintenance of your automatic welding machine extends its lifespan and ensures optimal performance:

Clean the Machine: Remove any residual spatter or contaminants after use. This includes cleaning the welding torch and nozzle.

Check Components: Periodically inspect and replace any worn or damaged components to prevent future issues.

Store Properly: Store the welding machine in a dry, secure location when not in use. Proper storage protects it from damage and prolongs its usability.

Conclusion

Operating an Automatic Drum Body Welding Machine can be a rewarding experience when approached with care and knowledge. By following the outlined steps, preparing adequately, and maintaining safety protocols, you can achieve high-quality welds and enhance your welding skills. Remember that consistent practice and ongoing learning are key to mastering welding techniques.

For more information about our welding solutions and to explore our resistance welding machine, please contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com. Your success in welding projects begins with the right knowledge and tools!

References

1. "Welding Basics: An Introduction to Welding." The Fabricator.

2. "Operating Welding Machines Safely." American Welding Society.

3. "Choosing the Right Welding Parameters." Lincoln Electric.

4. American Welding Society. (2021). Welding Handbook, 10th Edition.

5. Lincoln Electric. (2020). The Procedure Handbook of Arc Welding, 15th Edition.

6. Occupational Safety and Health Administration. (2022). Welding, Cutting, and Brazing Safety Guidelines.

7. International Organization for Standardization. (2019). ISO 3834: Quality requirements for fusion welding of metallic materials.