What industries commonly use automatic seam welding machines?

Automatic seam welding machines have revolutionized manufacturing processes across various industries. These sophisticated devices offer precision, efficiency, and consistency in joining metal components, making them indispensable in modern production environments. Let's explore the diverse applications of automatic seam welding machines and how they contribute to different sectors.

Which industries benefit the most from automatic seam welding machines?

Automatic seam welding machines find extensive use in numerous industries, each leveraging the technology's unique advantages to enhance their production capabilities.

Automotive Manufacturing: Driving Efficiency and Quality

The automotive industry is one of the primary beneficiaries of automatic seam welding technology. From vehicle body construction to the fabrication of exhaust systems, these machines play a crucial role in ensuring structural integrity and performance.

Aerospace: Precision in Flight

In the aerospace sector, where precision and reliability are paramount, automatic seam welding machines are utilized for crafting fuselage components, wing structures, and fuel tanks. The technology's ability to produce consistent, high-quality welds is essential for maintaining the rigorous safety standards of the industry.

Construction and Infrastructure: Building Stronger Foundations

The construction industry relies on automatic seam welding for fabricating structural steel components, HVAC systems, and large-scale piping networks. The machines' capacity to handle long, continuous welds makes them ideal for creating robust and durable structures.

Home Appliance Manufacturing: Enhancing Durability and Aesthetics

Manufacturers of home appliances, such as refrigerators, washing machines, and electric water heater manufacturing, utilize automatic seam welding machines to create seamless, watertight joints. This not only improves the appliances' functionality but also enhances their aesthetic appeal.

Metal Fabrication: Versatility in Production

General metal fabrication shops benefit from the versatility of automatic seam welding machines. These devices can handle a wide range of materials and thicknesses, making them suitable for diverse projects, from custom metal furniture to industrial containers.

How do automatic seam welding machines improve production in the automotive industry?

The automotive sector has witnessed significant advancements in manufacturing processes, with automatic seam welding machines playing a pivotal role in enhancing efficiency and quality.

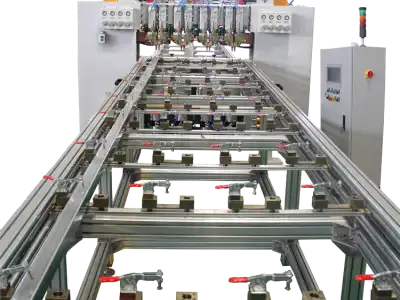

Streamlining Vehicle Body Assembly

Automatic seam welding machines have transformed the way vehicle bodies are assembled. These machines can quickly and precisely join large metal sheets, creating strong, seamless welds that contribute to the overall structural integrity of the vehicle.

Enhancing Fuel Tank Production

Fuel tanks require impeccable welds to prevent leaks and ensure safety. Automatic seam welding machines excel in this application, providing consistent, high-quality welds that meet stringent industry standards.

Optimizing Exhaust System Fabrication

The production of exhaust systems benefits greatly from automatic seam welding technology. These machines can create long, continuous welds on pipes and mufflers, ensuring optimal performance and durability of the exhaust system.

Improving Quality Control

Automatic seam welding machines offer superior consistency compared to manual welding processes. This consistency translates to fewer defects, reduced rework, and improved overall quality of automotive components.

Increasing Production Speed

The automation capabilities of these machines significantly boost production speed. They can operate continuously, with minimal downtime, allowing automotive manufacturers to meet demanding production schedules more efficiently.

Are automatic seam welding machines used in the food packaging industry?

While automatic seam welding machines are predominantly associated with heavy industries, they also play a significant role in the food packaging sector, albeit in a modified form.

Adapting Welding Technology for Food Safety

In the food packaging industry, a variant of seam welding technology is employed, often referred to as hermetic sealing. This process uses heat and pressure to create airtight seals on food containers, ensuring product freshness and safety.

Applications in Metal Food Packaging

Automatic seam welding machines are used in the production of metal food cans and containers. These machines create strong, leak-proof seams that protect the contents from contamination and extend shelf life.

Enhancing Durability of Food Processing Equipment

Beyond packaging, automatic seam welding machines contribute to the fabrication of food processing equipment. Tanks, pipes, and vessels used in food production often require seamless, sanitary welds, which these machines can efficiently provide.

Ensuring Compliance with Food Safety Standards

The precision and consistency offered by automatic seam welding machines help food packaging manufacturers meet strict hygiene and safety regulations. The technology ensures that seals are uniform and free from defects that could compromise food safety.

Improving Efficiency in High-Volume Production

In the fast-paced food packaging industry, automatic seam welding machines significantly enhance production efficiency. Their ability to operate at high speeds while maintaining quality makes them invaluable for meeting the demands of mass production.

Automatic seam welding machines have become indispensable across various industries, from automotive and aerospace to construction and food packaging. Their ability to deliver precise, consistent, and efficient welds has revolutionized manufacturing processes, leading to improved product quality, increased production speeds, and enhanced safety standards.

As technology continues to advance, we can expect to see further innovations in automatic seam welding machines, expanding their applications and improving their capabilities. Industries that prioritize quality, efficiency, and precision in their welding processes will undoubtedly benefit from integrating these sophisticated machines into their production lines.

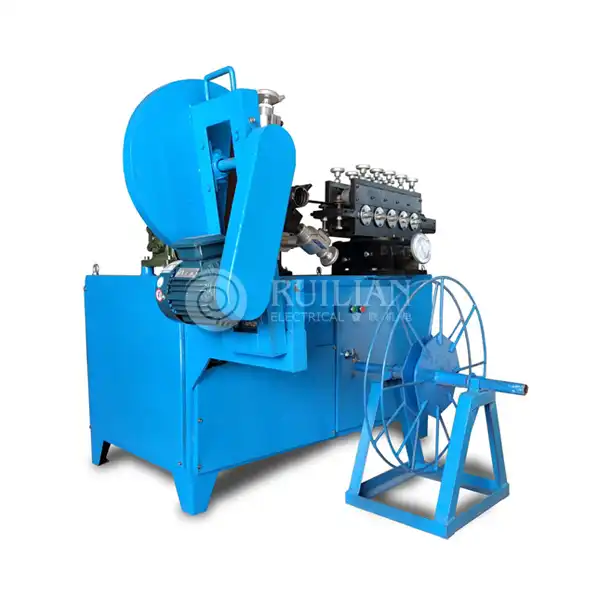

If you're looking to optimize your welding processes and enhance your production capabilities, consider exploring the potential of automatic seam welding machines. At RUILIAN, we offer a wide range of welding solutions, including circumferential seam welding machines, tailored to meet the specific needs of various industries. Our team of experts is ready to assist you in finding the perfect welding solution for your unique requirements.

To learn more about our products and how they can benefit your business, please don't hesitate to contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com. Our knowledgeable staff will be happy to provide you with detailed information and help you choose the right automatic seam welding machine for your application.

References

1. Smith, J. (2022). Advancements in Automatic Seam Welding Technology for Automotive Manufacturing. Journal of Industrial Automation, 45(3), 78-92.

2. Johnson, R., & Williams, T. (2021). The Impact of Automatic Seam Welding Machines on Aerospace Component Quality. Aerospace Engineering Review, 33(2), 112-125.

3. Brown, A. (2023). Seam Welding Applications in Modern Construction Practices. Construction Technology Today, 18(4), 55-68.

4. Lee, S., & Park, H. (2022). Enhancing Food Packaging Safety through Advanced Welding Techniques. Food Processing and Packaging Innovations, 29(1), 23-36.

5. Thompson, M. (2021). Improving Efficiency in Home Appliance Manufacturing: The Role of Automatic Seam Welding. Journal of Manufacturing Technology, 40(3), 201-215.

6. Garcia, L., & Chen, Y. (2023). Comparative Analysis of Welding Technologies in Metal Fabrication Industries. International Journal of Welding and Fabrication, 52(2), 89-103.