How many types of welding machine?

Welding is an indispensable process in various industries, from construction to manufacturing. The diversity of welding applications has led to the development of numerous types of welding machines, each designed to meet specific needs. In this comprehensive guide, we'll explore the various types of welding machines available, with a special focus on the versatile Resistance Arc Seam Welding Machine.

Understanding the Basics of Welding Machines

Welding machines are essential tools that use heat to join metals or thermoplastics. They come in various forms, each suited for different materials, thicknesses, and project requirements. The choice of welding machine depends on factors such as the type of metal, the thickness of the material, the welding position, and the desired weld quality.

Some common types of welding machines include:

1. Stick Welders (Shielded Metal Arc Welding - SMAW)

2. MIG Welders (Metal Inert Gas - GMAW)

3. TIG Welders (Tungsten Inert Gas - GTAW)

4. Flux-Cored Arc Welders (FCAW)

5. Plasma Arc Welders (PAW)

6. Submerged Arc Welders (SAW)

Among these, the Resistance Arc Seam Welding Machine stands out for its unique capabilities in continuous welding applications.

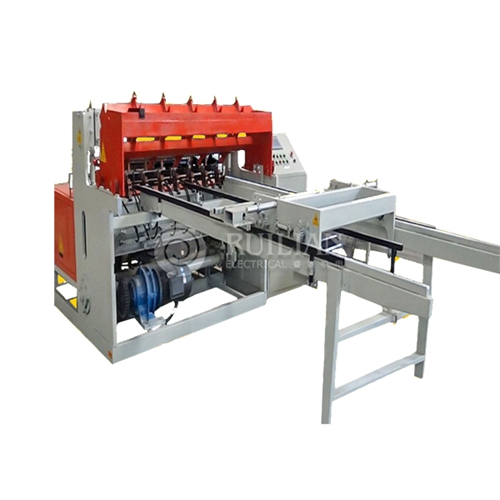

Exploring the Resistance Arc Seam Welding Machine

The Resistance Arc Seam Welding Machine is a specialized type of welding equipment that combines the principles of resistance welding and arc welding. This innovative machine is designed for continuous welding of long seams, making it ideal for applications in industries such as automotive, aerospace, and manufacturing.

The Resistance Arc Seam Welding Machine offers several key features that make it an invaluable tool in various manufacturing processes. One of its standout capabilities is continuous welding, which allows for the efficient joining of long seams without the need for frequent pauses or adjustments. This feature is particularly beneficial in industries where high volumes of work are required, such as automotive and aerospace manufacturing.

In addition to continuous operation, this machine boasts high welding speeds, significantly enhancing productivity on the production line. Faster welding processes mean that projects can be completed in less time, allowing manufacturers to meet tight deadlines and increase overall output.

Another essential aspect of this machine is its precise control over welding parameters. Operators can easily adjust settings such as current, voltage, and speed to achieve the desired weld characteristics. This level of precision ensures that the welds are not only strong but also tailored to specific material types and thicknesses, accommodating a range of applications.

Moreover, the Resistance Arc Seam Welding Machine is suitable for welding thin to medium-thickness materials, making it versatile for different projects. Whether working with delicate components or sturdier sections, this machine delivers reliable results.

Finally, the machine is known for producing excellent weld quality with minimal distortion. This is crucial in maintaining the integrity of the materials being welded, ensuring that the final product meets stringent quality standards without compromising structural strength. These features collectively make the Resistance Arc Seam Welding Machine a top choice for professionals seeking efficiency and reliability in their welding operations.

The China welding machine excels in applications where long, continuous welds are required, such as in the production of fuel tanks, pipes, and metal containers. Its ability to produce high-quality welds at rapid speeds makes it a valuable asset in many manufacturing processes.

Advantages and Applications of Different Welding Machines

Each type of welding machine offers unique advantages and is suited for specific applications. Let's explore some of these in more detail:

Stick Welders (SMAW)

Stick welders are versatile and portable, making them suitable for outdoor and construction work. They excel in welding thicker materials and can be used in various positions. However, they require more skill to operate and produce more spatter compared to other methods.

MIG Welders (GMAW)

MIG welders are known for their ease of use and clean welds. They're ideal for thin to medium-thickness materials and are commonly used in automotive repair and manufacturing. MIG welders offer high productivity but may struggle with outdoor use due to wind affecting the shielding gas.

TIG Welders (GTAW)

TIG welders produce high-quality, precise welds and are excellent for thin materials and non-ferrous metals. They're commonly used in aerospace, automotive, and artwork applications. TIG welding requires more skill and is slower compared to other methods but offers superior control and weld quality.

Flux-Cored Arc Welders (FCAW)

FCAW welders are similar to MIG welders but use a special flux-cored wire. They're ideal for outdoor use and thick materials, making them popular in construction and heavy fabrication. FCAW offers high deposition rates but can produce more fumes compared to other methods.

Plasma Arc Welders (PAW)

Plasma arc welders use a constricted arc and offer high precision and penetration. They're excellent for automated welding processes and can weld a wide range of materials, including exotic metals. PAW is commonly used in aerospace and high-precision manufacturing.

Submerged Arc Welders (SAW)

SAW machines are designed for high-volume, high-deposition welding of thick materials. They're commonly used in shipbuilding, heavy equipment manufacturing, and large pipe production. SAW offers excellent weld quality and penetration but is limited to flat and horizontal positions.

Resistance Arc Seam Welding Machine

As mentioned earlier, the Resistance Arc Seam Welding Machine combines the benefits of resistance and arc welding. It's particularly adept at producing long, continuous welds on thin to medium-thickness materials. This machine is invaluable in industries requiring high-speed, high-quality welding of long seams, such as in the production of metal containers, automotive body panels, and HVAC components.

The Resistance Arc Seam Welding Machine's ability to produce consistent, high-quality welds at rapid speeds makes it a game-changer in many manufacturing processes. Its precision control over welding parameters allows for optimal results even with challenging materials or complex geometries.

Conclusion

In conclusion, the world of welding machines is diverse and continually evolving to meet the demands of various industries. From the versatile stick welders to the specialized Resistance Arc Seam Welding Machine, each type of welding equipment plays a crucial role in modern manufacturing and construction processes. Understanding the strengths and applications of different welding machines is key to choosing the right equipment for your specific needs.

At RUILIAN, we pride ourselves on being a reliable welding and complete equipment supplier. Our extensive range of application solutions caters to welding products of different materials, sizes, and thicknesses, complemented by supporting processing equipment. Our advantage is a leading air duct welding manufacturing company related to air duct manufacturing in the HVAC industry. We have established excellent use cases across various industries, including ventilation engineering, home appliance manufacturing, aerospace, and marine vessels. To learn more about our products and how we can meet your welding needs, please don't hesitate to contact us at ry@china-ruilian.cn, or visit our website at www.rlseamwelding.com for more information.

References

1. American Welding Society. (2022). Welding Handbook, 10th Edition.

2. Lincoln Electric. (2021). The Procedure Handbook of Arc Welding, 15th Edition.

3. Kou, S. (2003). Welding Metallurgy, 2nd Edition. John Wiley & Sons.

4. O'Brien, R.L. (Ed.). (1991). Welding Handbook: Welding Processes, Vol. 2, 8th Edition. American Welding Society.

5. TWI Ltd. (2023). Types of Welding Processes.