Welding is a critical process in many manufacturing sectors, including ventilation engineering, home appliance manufacturing, aerospace, and marine vessel construction. The choice between automatic and semi-automatic welding machines can significantly impact production speed, quality, and overall efficiency. As we explore these differences, we'll provide insights that can help you make informed decisions about which type of welding machine best suits your needs.

The Fundamental Differences in Operation

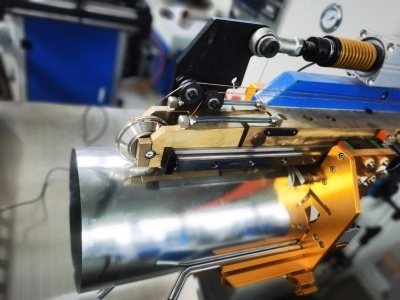

The primary distinction between automatic and semi-automatic welding machines lies in the level of human intervention required during the welding process. Automatic welding machines, exemplified by the Automatic Drum Body Welding Machine, are engineered to execute welding tasks with minimal human input. Once properly set up and programmed, these machines can autonomously handle the entire welding process, from accurately positioning the workpiece to completing the weld with precision. This autonomy not only enhances efficiency but also ensures consistent quality across multiple welds, making them particularly suitable for high-volume manufacturing environments.

In contrast, semi-automatic welding machines necessitate a greater degree of hands-on involvement from the operator. While these machines automate certain critical aspects of the welding process—such as wire feeding and controlling welding speeds—the welder still plays a crucial role in guiding the welding gun manually and managing the arc's stability. This blend of automated features and manual control allows operators to maintain flexibility and adapt to varying project requirements while still benefiting from the efficiency of automated processes.

The Automatic Drum Body Welding Machine showcases the remarkable capabilities of fully automated welding systems. Designed specifically for welding drum bodies, these machines excel in delivering unmatched consistency and efficiency in drum manufacturing. By automating not only the welding process but also workpiece positioning, adjustment of welding parameters, and quality control measures, they significantly reduce production times while maintaining high-quality welds. Furthermore, the implementation of such advanced automated systems can lead to decreased labor costs and increased safety, as the need for constant human supervision is minimized. In summary, while both automatic and semi-automatic machines serve important roles in the welding industry, the choice between them depends on the specific requirements of the production process and the desired balance between automation and human control.

Operational Efficiency and Production Speed

When it comes to operational efficiency and production speed, resistance welding machines generally have a significant advantage. For instance, the Automatic Drum Body Welding Machine is engineered to maintain a consistent welding speed and high-quality output throughout long production runs. This level of consistency is often challenging to achieve with semi-automatic welding processes, where human factors—such as operator fatigue or variations in technique—can significantly influence the quality of the welds.

Automatic welding machines are particularly well-suited for high-volume production environments, where repeatability is essential. These machines can operate continuously for extended periods, dramatically reducing downtime and leading to increased overall productivity. Their precision engineering minimizes the likelihood of defects, which in turn reduces the need for rework and enhances efficiency across the production line.

In contrast, while semi-automatic welding machines may not match the speed of their fully automated counterparts, they offer greater flexibility. This makes them ideal for smaller production runs or tasks that require frequent changes in welding parameters. The human element in semi-automatic welding allows operators to make real-time adjustments, enabling these machines to tackle a wider variety of welding tasks effectively. This adaptability can be crucial in environments where project specifications change frequently.

It is important to acknowledge that the initial setup time for automatic welding machines, including models like the Automatic Drum Body Welding Machine, can be longer compared to semi-automatic systems. This upfront investment in time and resources is often offset by the machine’s ability to deliver increased production speed and consistent quality once operational. Over time, the advantages of automation can lead to significant cost savings and improved manufacturing outcomes, making them a worthwhile consideration for companies focused on maximizing efficiency and maintaining high production standards.

Quality Control and Precision

Quality control is a critical aspect of any welding operation, and both automatic and semi-automatic welding machines offer distinct advantages in this area. Automatic welding machines, particularly advanced models like the Automatic Drum Body Welding Machine and automatic spot welding machine, incorporate sophisticated quality control mechanisms. These may include real-time monitoring of welding parameters, automated defect detection, and precise control over weld penetration and bead geometry.

The consistency provided by automatic welding machines is unparalleled. Once the optimal welding parameters are set, the machine can reproduce these conditions with remarkable accuracy, weld after weld. This level of consistency is especially valuable in industries with stringent quality requirements, such as aerospace or pressure vessel manufacturing.

Semi-automatic welding machines rely more heavily on the skill of the operator for quality control. While these machines often include features like synergic control to help maintain optimal welding parameters, the human element introduces variability. However, this can also be an advantage in certain situations. Skilled welders can make nuanced adjustments based on visual and auditory cues, allowing for adaptability in complex welding scenarios.

The Automatic Drum Body Welding Machine shines in applications where weld quality is paramount. These machines can achieve precise, uniform welds along the entire length of a drum body, ensuring structural integrity and leak-free performance. The automated quality control systems in these machines can detect and flag potential issues in real-time, allowing for immediate corrective action.

In conclusion, the choice between automatic and semi-automatic welding machines depends on various factors, including production volume, required flexibility, and the specific welding application. Automatic welding machines, like the Automatic Drum Body Welding Machine, offer unmatched efficiency and consistency for high-volume, repetitive welding tasks. Semi-automatic welding machines provide greater versatility and are well-suited for smaller production runs or more diverse welding requirements.

As industries continue to evolve, the demand for efficient and precise welding solutions grows. RUILIAN remains at the forefront of this evolution, offering cutting-edge welding equipment to meet diverse industrial needs. Whether you're considering an Automatic Drum Body Welding Machine or exploring other welding solutions, our team of experts is ready to assist you in finding the perfect fit for your operations. Contact us at ry@china-ruilian.cn or visit www.rlseamwelding.com to discover how our welding solutions can elevate your manufacturing processes.