How does a welding machine work?

Welding is a crucial process in various industries, from construction to manufacturing. At the heart of this process lies the welding machine, a sophisticated piece of equipment that joins metals together with precision and strength. In this article, we'll explore the inner workings of welding machines, with a special focus on the Resistance Straight Seam Welding Machine, a specialized tool that's revolutionizing certain sectors of the welding industry.

The Basics of Welding Machines

At its core, a welding machine is designed to generate and control the heat necessary to melt and fuse metals. This process involves creating an electric arc between an electrode and the base metal. The arc's intense heat melts the metals at the joint, allowing them to mix and form a strong bond upon cooling.

Modern welding machines come in various types, each suited for specific applications. These include arc welders, MIG (Metal Inert Gas) welders, TIG (Tungsten Inert Gas) welders, and plasma cutters. Each type utilizes different mechanisms to achieve the same goal: joining metals efficiently and effectively.

One of the more specialized types of welding machines is the Resistance Straight Seam Welding Machine. This particular equipment is designed for continuous welding of long, straight seams, making it invaluable in industries that require the production of pipes, tubes, and other cylindrical objects.

Understanding Resistance Straight Seam Welding

Resistance Straight Seam Welding is a unique process that differs from traditional arc welding methods. Instead of using an external heat source, this technique relies on the principle of electrical resistance to generate heat. When an electric current passes through the metal pieces to be joined, it encounters resistance, which generates heat at the point of contact.

The Resistance Straight Seam Welding Machine capitalizes on this principle. It uses two copper alloy wheels as electrodes, which roll along the edges of the metal sheets to be joined. As the wheels move, they apply pressure and pass a high-amperage current through the metal. The resistance at the interface of the two metal sheets causes localized heating, melting the metal and creating a continuous weld seam.

This method is particularly effective for joining thin metal sheets, as it provides a clean, uniform weld without the need for filler material. The process is also quite fast and can be easily automated, making it ideal for high-volume production environments.

Components and Operation of a Resistance Straight Seam Welding Machine

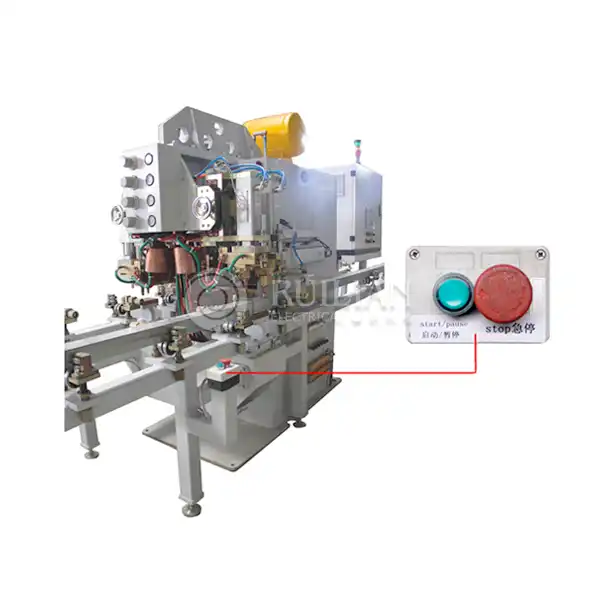

A typical Resistance Straight Seam Welding Machine consists of several key components:

- Welding wheels: These copper alloy wheels serve as electrodes and apply pressure to the workpiece.

- Power supply: A transformer that provides the high current necessary for welding.

- Cooling system: This prevents overheating of the welding wheels and other components.

- Control system: Manages the welding parameters such as current, pressure, and speed.

- Feeding mechanism: Guides the metal sheets through the machine at a consistent speed.

The operation of a stitchwelder is a marvel of engineering. As the metal sheets are fed into the machine, they pass between the welding wheels. These wheels apply pressure to ensure good contact between the sheets. Simultaneously, a high-amperage current is passed through the wheels and into the metal.

The resistance at the interface of the two sheets causes rapid heating, melting the metal at the point of contact. As the sheets continue to move through the machine, this process creates a continuous weld seam. The pressure applied by the wheels helps to forge the molten metal together, creating a strong, uniform bond.

One of the key advantages of this process is its efficiency. The Resistance Straight Seam Welding Machine can produce long, continuous welds at high speeds, making it ideal for manufacturing pipes, tubes, and other cylindrical products. The process is also quite clean, as it doesn't require any filler material or shielding gas, reducing waste and simplifying the welding environment.

Moreover, the precise control offered by modern Resistance Straight Seam Welding Machines allows for fine-tuning of welding parameters. This ensures consistent weld quality even with variations in material thickness or composition. The ability to maintain such high standards of quality while operating at high speeds is what makes these machines so valuable in industrial settings.

In industries such as automotive manufacturing, HVAC production, and pipeline construction, the Resistance welding Machine has become an indispensable tool. Its ability to produce high-quality, consistent welds at a rapid pace has significantly improved production efficiency and product quality in these sectors.

As welding technology continues to evolve, we can expect to see further advancements in Resistance Straight Seam Welding Machines. Innovations in materials science may lead to more durable welding wheels, while improvements in control systems could allow for even greater precision and efficiency. The integration of artificial intelligence and machine learning could potentially enable these machines to automatically adjust welding parameters based on real-time feedback, further enhancing their capabilities.

Conclusion

In conclusion, welding machines, particularly specialized equipment like the Resistance Straight Seam Welding Machine, play a crucial role in modern manufacturing and construction. By understanding how these machines work, we can better appreciate the complexity and precision involved in creating the metal products we use every day. Whether you're a professional in the welding industry or simply curious about the technology behind everyday objects, the world of welding machines offers fascinating insights into the intersection of physics, engineering, and industrial design.

At RUILIAN, we pride ourselves on being at the forefront of welding technology. As a reliable welding and complete equipment supplier, we offer a wide range of application solutions, including state-of-the-art Resistance Straight Seam Welding Machines. Our expertise extends to welding products of different materials, sizes, and thicknesses, as well as providing supporting processing equipment. We have excellent use cases in ventilation engineering, home appliance manufacturing, aerospace, marine vessels, and other fields. If you want to learn more about our products or discuss how our welding solutions can benefit your operations, we welcome you to contact us at ry@china-ruilian.cn and you can view our company website: www.rlseamwelding.com.

References

1. American Welding Society. (2021). Welding Handbook, 10th Edition.

2. Lincoln Electric. (2020). The Procedure Handbook of Arc Welding, 15th Edition.

3. Kou, S. (2003). Welding Metallurgy, 2nd Edition. Wiley-Interscience.

4. Resistance Welding Manufacturing Alliance. (2019). Resistance Welding Manual, 4th Edition.

5. O'Brien, R. L. (Ed.). (1991). Welding Handbook: Welding Processes, Vol. 2. American Welding Society.