What industries commonly use air duct rubber ring machines?

Air duct rubber ring machines play an essential role in fabricating airtight ducts for various systems, enhancing performance and reducing energy losses. These machines are widely used across multiple industries where ventilation, heating, and cooling systems are critical. The ability to create airtight seals with precision is vital to ensure efficiency and prevent costly energy leaks. In this blog, we will explore the key industries that rely on the Air Duct Rubber Ring Machine, highlighting its versatility and importance.

HVAC Systems and Building Construction

The Heating, Ventilation, and Air Conditioning (HVAC) industry is one of the largest users of air duct rubber ring machines. HVAC systems are essential for regulating temperature, preserving indoor air quality, and maximizing energy efficiency in both residential and commercial buildings. The Air Duct Rubber Ring Machine is necessary for creating airtight seals within duct systems, preserving optimal airflow and significantly reducing energy waste.

Numerous advantages for buildings can be derived from efficient HVAC systems, such as decreased operational costs, decreased energy consumption, and improved indoor air quality. Leaks are effectively prevented when rubber rings are used to seal ducts. This is important because even small leaks can cause a lot of inefficiencies. These inefficiencies can have a negative impact on a building's level of comfort as well as raise energy costs. Investing in high-quality air duct rubber ring machines streamlines production processes for HVAC contractors and manufacturers, allowing for consistent results and ensuring that ducts are constructed to strict performance standards.

In addition, in order to comply with evolving energy efficiency regulations, the construction industry places an increasing emphasis on the installation of high-quality ventilation systems in new buildings. Air duct rubber ring machines are essential tools for HVAC professionals and builders alike because adhering to these regulations requires ducts to be properly sealed. These machines contribute to the development of systems that are not only compliant but also sustainable over the course of time by making certain that each duct is constructed with precision and dependability.

In conclusion, the Air Duct Rubber Ring Machine is essential for increasing HVAC systems' performance and effectiveness. It supports both energy conservation efforts and the overall comfort of indoor environments, so its role in the production of airtight seals cannot be overstated. These machines will only gain in importance in the HVAC and construction industries as the demand for energy-saving solutions continues to rise.

Aerospace and Marine Industries

Another industry where the Air Duct Rubber Ring Machine plays a crucial role is aerospace. In this highly regulated sector, aircraft ventilation systems must adhere to stringent safety and efficiency standards to ensure both passenger comfort and safety during flights. The airtight sealing of air ducts is essential for maintaining stable air pressure and effective climate control within aircraft cabins. Any compromise in these seals can lead to uncomfortable conditions and even safety hazards. With the assistance of air duct rubber ring machines, manufacturers in the aerospace sector are able to produce ducts that are precisely sealed, significantly reducing the risk of system failures or air pressure leaks. This precision not only enhances passenger comfort but also ensures compliance with aviation regulations.

Similarly, the marine industry places a high importance on airtight ventilation systems, particularly in ships and submarines. These vessels often operate in challenging environments where maintaining proper airflow is critical for both operational efficiency and crew safety. The air duct rubber ring machine is instrumental in producing ducts that can withstand harsh marine conditions, ensuring reliable performance over time. Properly sealed air ducts help to prevent the infiltration of water and contaminants, which could jeopardize the integrity of the vessel and the safety of its crew.

Moreover, the consistent and reliable seals produced by these machines contribute to extending the longevity of the ventilation systems used on ships. By minimizing the chances of leaks and system malfunctions, maintenance requirements are reduced, leading to less downtime and more efficient operations. In both aerospace and marine applications, the role of air duct rubber ring machines cannot be overstated; they are vital for creating systems that enhance safety, efficiency, and reliability in some of the most demanding environments. As industries continue to push for higher standards, the importance of these machines will only grow, ensuring that both aircraft and marine vessels can operate safely and effectively.

Industrial Manufacturing and Large-Scale Facilities

In large-scale manufacturing plants and industrial facilities, ventilation is critical to ensure worker safety and maintain the performance of equipment. Factories often produce dust, fumes, and gases that need to be efficiently vented out of the workspace. Proper ductwork is essential to ensure harmful particles and gases are removed, and using an Air Duct Rubber Ring Machine ensures that ducts remain tightly sealed, preventing leaks and maintaining airflow integrity.

Industrial facilities, especially those that handle hazardous materials, require well-sealed ducts to prevent the escape of dangerous gases or chemicals. Rubber ring machines offer a consistent and efficient solution for creating tight, reliable seals in such environments. In facilities where production cannot afford downtime due to ventilation failures, the Air Duct Rubber Ring Machine helps ensure that duct systems function reliably, reducing the risk of costly interruptions.

Moreover, the use of air duct rubber ring machines in these settings ensures that ducts are manufactured with consistent quality, reducing the need for frequent inspections and repairs. This increases the overall efficiency of industrial facilities, allowing them to maintain a safe and productive working environment.

Conclusion

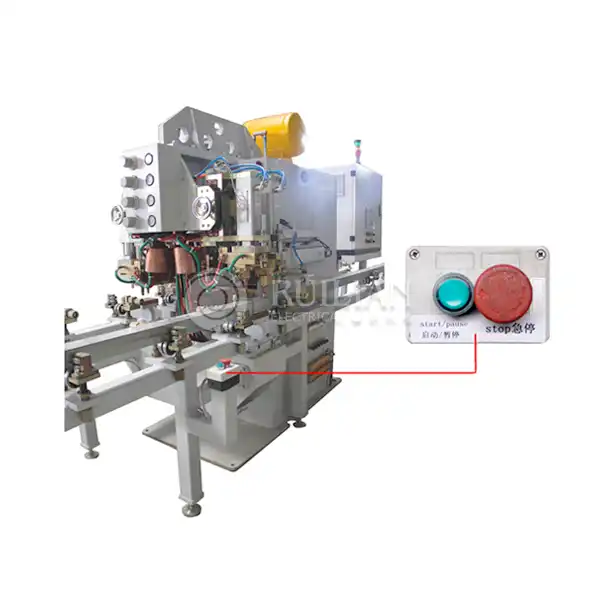

RUILIAN stands as a trusted manufacturer and supplier of the air duct seal, boasting extensive experience in production and innovation. At RUILIAN, we provide high-quality air duct fabrication solutions, including the Air Duct Rubber Ring Machine, to meet the needs of various industries. Whether you’re in the HVAC, aerospace, marine, or manufacturing sector, our products are designed to ensure precision and efficiency in your ductwork. For more information, contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com.

References

1. Shaanxi RUILIAN Seam Welding Equipment Co., Ltd. - Air Duct Fabrication Machines

2. HVAC Duct Systems and Energy Efficiency – Industry Report

3. Ventilation Systems in Aerospace Engineering – Technical Journal

4. Marine Ventilation Systems and Equipment – Manufacturing Insights

5. Industrial Duct Sealing and Ventilation – Engineering Case Studies