What Industries Use Steel Drum Automatic Welding Machines?

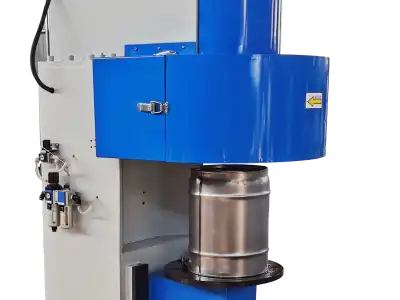

Steel Drum Automatic Welding Machines have become indispensable tools in a variety of industries, offering superior precision, speed, and efficiency in the production of steel drums. These machines are used to manufacture steel drums with high structural integrity and minimal human intervention, making them an essential piece of equipment in sectors that require robust, reliable, and cost-effective packaging solutions. In this blog, we’ll explore how these machines benefit the chemical, logistics, and packaging industries, and highlight the importance of welding technology in these critical fields.

How Do Steel Drum Automatic Welding Machines Benefit the Chemical Industry?

The chemical industry relies heavily on steel drums for storing and transporting hazardous chemicals, solvents, and other sensitive materials. Steel drums offer excellent protection from environmental factors and ensure the integrity of their contents. Steel Drum Automatic Welding Machines play a crucial role in the production of these drums, ensuring that each drum is welded to perfection and free of leaks.

Precision for Hazardous Materials

When it comes to storing chemicals, the need for precision is paramount. The use of an automatic welding machine in the production of steel drums guarantees that each seam is perfectly welded, preventing any potential leakage of hazardous chemicals. This is especially important for substances that can cause harm to the environment or pose a risk to human health.

Speed and Efficiency

In the chemical industry, time is of the essence, especially when it comes to large-scale production. Steel Drum Automatic Welding Machines, equipped with resistance welding machine technology, are designed for high throughput, which enables manufacturers to produce steel drums quickly and efficiently, without compromising on the quality of the welds. This efficiency helps meet the high demand for chemical storage containers while keeping production costs under control.

Safety and Compliance

Safety is a major concern in the chemical industry, and automatic welding machines help ensure compliance with safety standards. A well-welded steel drum with no defects is crucial for safe storage and transportation of chemicals. These machines reduce the risk of human error and help meet industry regulations that demand leak-proof, durable packaging.

What Role Do Automatic Welding Machines Play in the Logistics and Shipping Industry?

In the logistics and shipping industry, steel drums are often used to store and transport a variety of materials, from industrial liquids to food products. Steel drums offer durability and ease of handling, making them ideal for large-scale transportation. Automatic welding machines help improve the efficiency, precision, and quality of steel drum production, which directly impacts the logistics and shipping process.

Efficient Mass Production for Shipping Needs

Steel drums are frequently used for bulk shipments, and the demand for these containers is high. Automatic welding technology allows manufacturers to produce steel drums quickly and in large quantities. These machines can continuously weld steel drum bodies, significantly increasing production speeds while maintaining consistent weld quality. This ensures a steady supply of high-quality drums to meet the needs of the logistics and shipping industry.

Reduced Risk of Damaged Goods

When steel drums are improperly welded or sealed, there is a risk of leaks, which could lead to contamination or damage to the goods being transported. Resistance welding machines and automatic spot welding machines ensure that the steel drums are properly sealed, minimizing the risk of damage during transportation. A securely welded drum will hold up better under the pressures of international shipping, ensuring that products reach their destination safely and without contamination.

Cost-Effective Solutions

By streamlining the manufacturing process with automatic welding technology, companies in the logistics industry benefit from lower production costs. Automated systems require fewer manual labor hours, allowing manufacturers to pass on the savings to customers. This results in cost-effective steel drum solutions that help keep shipping costs manageable, which is especially important in industries like logistics where margin pressures are high.

Why Are Steel Drum Welding Machines Important for the Packaging Industry?

The packaging industry is one of the largest sectors that use steel drums as part of their packaging solutions. Steel drums are used to store and transport a wide variety of products, from chemicals to food and beverages. Automatic welding machines, including steel drum welding machines, ensure that the drums meet the necessary standards for durability and safety.

Consistent Quality for Packaging Demands

In the packaging industry, it’s crucial to maintain consistent quality across all products. Automatic welding machines ensure that each steel drum is welded with precision and consistency. This is especially important when it comes to packaging food, beverages, or other sensitive products that require contamination-free storage. The consistency provided by automated welding eliminates the risk of defects that can occur with manual welding.

Versatility for Different Product Types

Steel drums are versatile containers, used for a wide range of products. From heavy-duty industrial materials to more sensitive food-grade packaging, these drums must meet different requirements in terms of strength, size, and sealing. Automatic welding machines offer the flexibility to produce drums of various specifications, ensuring that manufacturers can cater to a wide array of packaging needs. Whether it’s for a heavy industrial product or a lightweight, food-safe container, the automatic welding machine can be adjusted to meet those demands.

Sustainability and Environmental Impact

With growing concerns about environmental impact and sustainability, companies in the packaging industry are increasingly turning to more efficient and eco-friendly manufacturing methods. Automatic welding technology can reduce material waste, lower energy consumption, and ensure that each steel drum is as efficient as possible. Additionally, steel is a recyclable material, and steel drum automatic welding machines help ensure that drums are constructed with durability in mind, extending the life of the product and contributing to a more sustainable packaging solution.

Conclusion

The role of Steel Drum Automatic Welding Machines in industries like chemicals, logistics, and packaging is crucial for ensuring the efficiency, safety, and quality of steel drum production. These machines offer precision, speed, and consistency that are critical for producing high-quality steel drums used in transporting and storing a wide variety of products. Whether it’s the chemical industry's need for leak-proof containers, the logistics sector's demand for cost-effective packaging, or the packaging industry's focus on quality and versatility, automatic welding machines are at the heart of steel drum manufacturing.

If you would like to learn more about how automatic welding solutions can benefit your production process or explore our wide range of welding equipment, feel free to contact us at ry@china-ruilian.cn or visit our website at www.rlseamwelding.com.

References

1. Advances in Welding Technology for Steel Drum Manufacturing.

2. The Role of Automatic Welding Machines in Industrial Manufacturing.

3. Steel Drum Production: Meeting the Demands of Chemical and Packaging Industries.

4. How Automation Enhances Production Speed in the Welding Industry.

5. Sustainability in Packaging: The Impact of Efficient Welding Technology.