Enhancing Speed and Precision in Welding Operations

One of the primary ways an automatic straight seam welding machine improves production efficiency is through its unparalleled speed and precision. Traditional manual welding methods, while effective, are often time-consuming and prone to human error. Automatic welding machines, on the other hand, can operate at consistently high speeds without compromising on quality.

These machines are equipped with advanced control systems that allow for precise adjustment of welding parameters such as speed, current, and voltage. This level of control ensures that each weld is performed with optimal settings, resulting in high-quality, uniform welds throughout the entire seam. The ability to maintain consistent welding parameters over long periods is particularly beneficial when working on large-scale projects or high-volume production runs.

Moreover, automatic straight seam welding machines can operate continuously for extended periods, far surpassing the endurance of human welders. This continuous operation capability translates to increased production output and reduced downtime. While a human welder might need frequent breaks to maintain focus and prevent fatigue, an automatic welding machine can work tirelessly, producing consistent results hour after hour.

The precision offered by these machines also contributes to efficiency by minimizing waste and rework. With manual welding, there's always a risk of defects or inconsistencies that may require correction. Automatic welding machines, however, produce welds with such consistency that the need for rework is significantly reduced. This not only saves time but also conserves materials, leading to cost savings in the long run.

Streamlining Production Processes with Automation

Automation is at the heart of how an automatic straight seam welding machine improves production efficiency. By removing the need for constant human intervention, these machines allow for a more streamlined and efficient production process.

In a typical manual welding setup, operators need to constantly monitor the welding process, make adjustments, and manually move the welding torch along the seam. This requires a high level of skill and concentration, and even the most experienced welders can struggle to maintain consistency over long periods. An automatic straight seam welding machine eliminates these challenges by handling all aspects of the welding process autonomously. The advantages of this cheap welding machine in this regard are very significant.

The automation extends beyond just the welding itself. Many modern automatic welding machines come equipped with features such as automatic part loading and unloading systems. These systems can be integrated with other production line equipment, creating a seamless workflow that minimizes the need for manual handling of materials. This not only speeds up the overall production process but also reduces the risk of workplace injuries associated with manual material handling.

Furthermore, automatic straight seam welding machines often incorporate advanced sensing and monitoring technologies. These systems can detect and adjust for variations in material thickness or joint alignment in real-time, ensuring optimal weld quality without the need for manual intervention. Some machines even feature self-diagnostic capabilities, alerting operators to potential issues before they become major problems, thus minimizing unexpected downtime.

The level of automation provided by these machines also allows for more flexible production scheduling. With the ability to operate around the clock with minimal supervision, manufacturers can optimize their production schedules to meet changing demand or tight deadlines. This flexibility can be a significant advantage in industries with fluctuating production requirements or seasonal variations in demand.

Improving Quality Control and Consistency

Quality control is a critical aspect of any manufacturing process, and welding is no exception. An automatic straight seam welding machine significantly enhances quality control measures, leading to improved overall product quality and consistency.

One of the key advantages of these machines is their ability to produce welds with exceptional consistency. Unlike manual welding, where quality can vary based on the welder's skill level or fatigue, automatic welding machines maintain the same high standard of quality throughout the entire production run. This consistency is crucial in industries where weld integrity is paramount, such as in the production of pressure vessels or structural components.

Many automatic straight seam welding machines are equipped with advanced monitoring systems that can track various welding parameters in real-time. These systems can detect even minor deviations from the set parameters and make instant adjustments to maintain optimal weld quality. Some machines even have the capability to record welding data for each seam, providing valuable information for quality assurance and traceability purposes.

The improved quality control offered by these machines also translates to reduced inspection and testing requirements. With manual welding, extensive post-weld inspections are often necessary to ensure weld quality. However, the consistent quality produced by automatic welding machines means that manufacturers can often reduce the frequency and extent of these inspections, further improving overall production efficiency.

Moreover, the precision of automatic welding machines contributes to improved product aesthetics. In industries where the appearance of welds is important, such as in the production of consumer goods or architectural components, the clean, uniform welds produced by these machines can enhance the overall look of the final product. This can lead to increased customer satisfaction and potentially higher product value.

Conclusion

In conclusion, an automatic straight seam welding machine is a powerful tool for improving production efficiency in welding operations. By enhancing speed and precision, streamlining processes through automation, and improving quality control, these machines offer significant advantages over traditional welding methods. As manufacturing continues to evolve, the adoption of such advanced technologies will be crucial for companies looking to maintain a competitive edge in their respective industries.

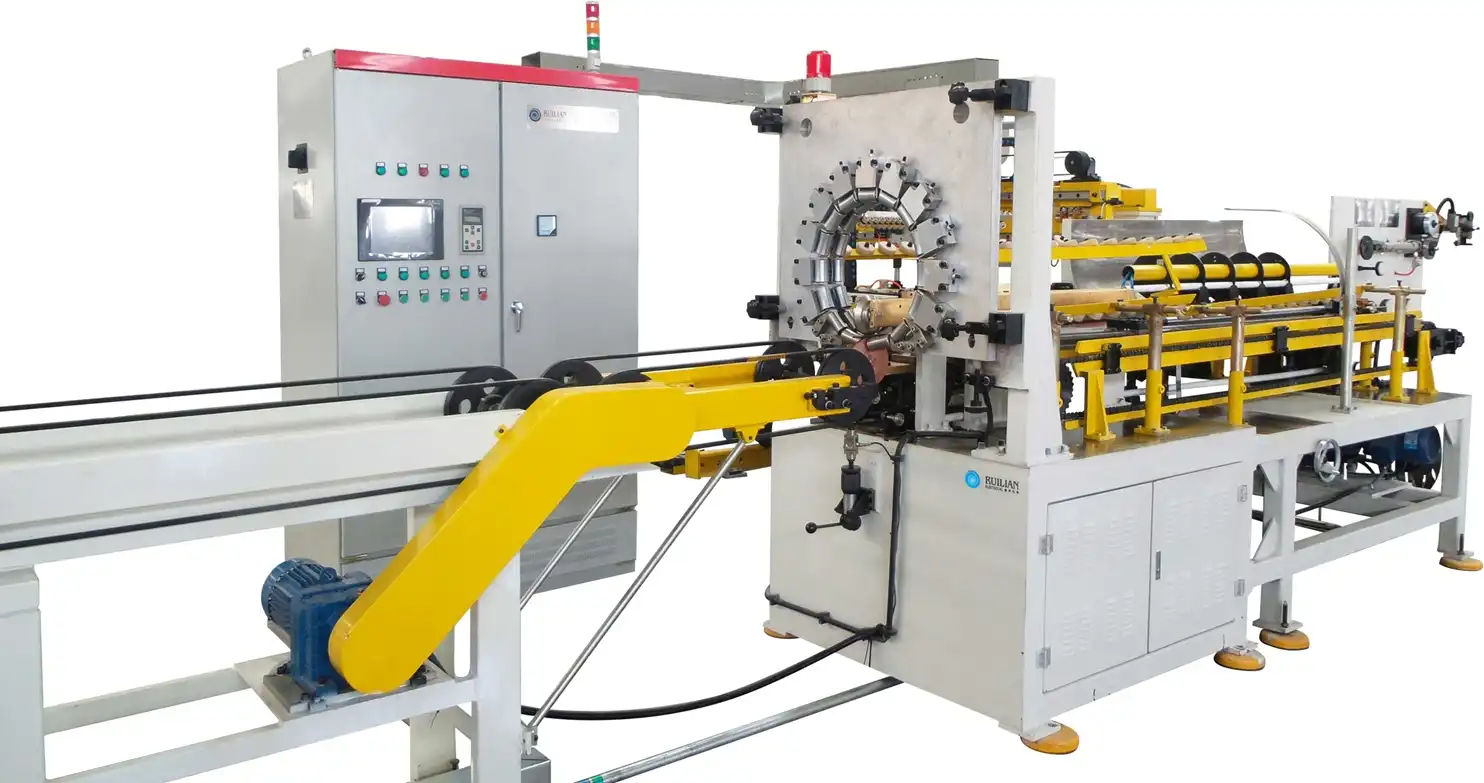

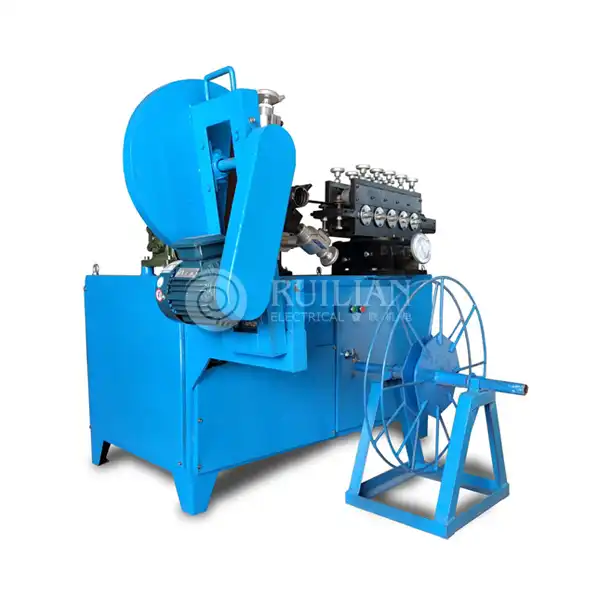

The automatic straight seam welding machine is utilized in the development of electric water heater manufacturing, apparatuses, hardware, and metal furnishings. If you're interested in learning more about how automatic straight seam welding machines can benefit your specific production needs, we invite you to explore our range of solutions. Visit our website at www.rlseamwelding.com for detailed product information, or reach out to our team of experts at ry@china-ruilian.cn. We're here to help you optimize your welding processes and drive your production efficiency to new heights.