Drum welding is a critical process in the production of various containers used across industries. From steel drums for chemical storage to large vessels for marine applications, efficient welding techniques are essential. However, traditional welding methods often consume substantial amounts of energy, leading to increased operational costs and environmental concerns. By implementing energy-efficient practices and leveraging advanced technologies like the Steel Drum Automatic Welding Machine, manufacturers can address these challenges head-on.

Optimizing Welding Parameters for Energy Conservation

Optimizing Welding Parameters for Energy Efficiency

One of the most effective ways to improve energy efficiency in drum welding operations is by optimizing welding parameters. This involves fine-tuning various aspects of the welding process to minimize energy consumption without compromising weld quality.

Critical Welding Parameters: Current and Voltage

Welding current and voltage are two critical parameters that significantly impact energy usage. By carefully adjusting these settings, it is possible to achieve optimal fusion while reducing overall power consumption. For instance, utilizing pulsed current techniques can help maintain weld integrity while lowering the average power input.

Precise Control with the Welding Machine

The Steel Drum Automatic Welding Machine offers precise control over these parameters, allowing for consistent and efficient welding. Its advanced control systems enable operators to set and maintain optimal welding conditions throughout the production run, resulting in substantial energy savings.

Increasing Welding Speed to Save Energy

Another crucial factor is welding speed. Increasing the welding speed can lead to reduced energy consumption per unit length of weld. However, this must be balanced with maintaining weld quality. The Steel Drum Automatic Welding Machine's high-speed capabilities, combined with its precise control, allow for faster welding without sacrificing quality, thus enhancing energy efficiency.

Choosing the Right Consumables for Energy Conservation

Proper selection of welding consumables also plays a role in energy conservation. Using high-quality electrodes or filler materials that are well-suited to the base metal can improve weld efficiency and reduce the need for multiple passes, thereby saving energy.

Implementing Advanced Welding Technologies

Adopting advanced welding technologies is another effective strategy for improving energy efficiency in drum welding operations. These technologies often incorporate innovative features designed to optimize energy usage while enhancing weld quality and productivity.

State-of-the-Art Welding Techniques for Energy Savings

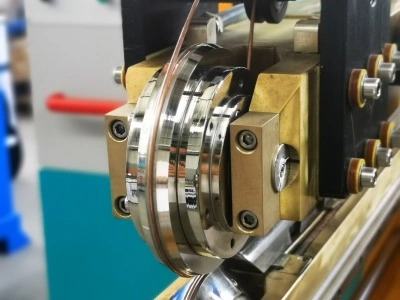

The Steel Drum Automatic Welding Machine exemplifies this approach. It utilizes state-of-the-art welding techniques such as submerged arc welding (SAW) or gas metal arc welding (GMAW), which are known for their energy efficiency. These processes offer high deposition rates and deep penetration, reducing the number of passes required and, consequently, the overall energy consumption.

Automation to Eliminate Inefficiencies

Moreover, the machine's automated nature eliminates many of the inefficiencies associated with manual welding. It maintains consistent welding parameters throughout the operation, preventing energy waste due to human error or fatigue. The precise control over arc stability and weld pool dynamics further contributes to energy conservation.

Power Source Inverter Technology and Adaptive Control Systems

Another advanced feature of modern welding systems is power source inverter technology. Inverter-based power sources are significantly more energy-efficient than traditional transformer-based units. They convert input power to high-frequency AC before rectifying it to DC, resulting in lighter, more efficient equipment that consumes less power during operation and idle periods.

Some cutting-edge Steel Drum Automatic Welding Machines also incorporate adaptive control systems. These systems continuously monitor the welding process and make real-time adjustments to maintain optimal performance. By constantly fine-tuning parameters based on feedback, these machines can achieve maximum energy efficiency under varying conditions.

Enhancing Operational Practices for Reduced Energy Consumption

While technological advancements play a crucial role in improving energy efficiency, optimizing operational practices is equally important. By refining workflows and implementing energy-conscious procedures, manufacturers can significantly reduce their overall energy consumption in drum welding operations.

Proper maintenance

One key aspect is proper maintenance of welding equipment, including the resistance welding machine. Regular maintenance ensures that all components are functioning at peak efficiency, preventing energy waste due to worn or malfunctioning parts. This includes cleaning welding nozzles, checking and replacing cables, and calibrating sensors and control systems.

Efficient production planning

Efficient production planning is another vital factor. By optimizing the sequence of welding operations and minimizing idle time between welds, manufacturers can reduce overall energy consumption. The Steel Drum Automatic Welding Machine's high-speed capabilities and quick setup times contribute to this efficiency, allowing for seamless transitions between welding tasks.

Employee training

Employee training is also crucial for energy-efficient operations. Operators should be well-versed in the energy-saving features of the Steel Drum Automatic Welding Machine and trained to use them effectively. This includes understanding how to set optimal welding parameters, recognize signs of inefficiency, and perform basic troubleshooting to maintain peak performance.

Implementing energy monitoring systems

Implementing energy monitoring systems can provide valuable insights into consumption patterns, helping identify areas for improvement. Some advanced Steel Drum Automatic Welding Machines come equipped with built-in energy monitoring features, allowing manufacturers to track and analyze energy usage in real-time.

Lastly, considering the entire production ecosystem is essential. This includes optimizing material handling processes, ensuring proper insulation of the welding area to prevent heat loss, and even exploring the use of renewable energy sources to power welding operations. While the Steel Drum Automatic Welding Machine focuses on the welding process itself, these peripheral considerations can contribute significantly to overall energy efficiency.

In conclusion, improving energy efficiency in drum welding operations requires a multifaceted approach. By optimizing welding parameters, implementing advanced technologies like the Steel Drum Automatic Welding Machine, and enhancing operational practices, manufacturers can achieve substantial energy savings. These efforts not only reduce costs but also contribute to a more sustainable manufacturing process, aligning with global efforts to minimize industrial energy consumption and environmental impact.

For those seeking to elevate their drum welding operations with energy-efficient solutions, RUILIAN offers expert guidance and cutting-edge equipment. Visit www.rlseamwelding.com or reach out to us at ry@china-ruilian.cn to explore how our Steel Drum Automatic Welding Machines and other advanced welding solutions can transform your manufacturing processes.